Alan_F

New Member

Wel ignore the last post as regards the head stop being on the side it doesnt work for upwards end stop its for the downwards motion.

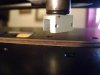

but i sorted it all out, anyway, i removed the head from the carriage, and tipped it upside down and filled it with isopronal alcohol or ipa (get it from maplins) then i just worked the head unit in and out and used cotton buds to clean the lip of the coil and the shaft, also make sure the little brass bearing is seated in its base as mine was coming out a bit

its now cutting fine at 75g pressure through standard 3 to 5 year vinyl, and just leaving a slight indent in the backing paper, one last thing make sure you dont get ipa in the encoder motor it will run through and cause the encoder not to work till it completely dries out, so i hope this solves your T750, T1400 or whatever summa tangential head sticking problem you have, just added that so peeps can find this thread, as i searched for ages, also if anyone has any further info on summa's please post as its better than paying 1000's of pounds or dollars to get them fixed

Alan

but i sorted it all out, anyway, i removed the head from the carriage, and tipped it upside down and filled it with isopronal alcohol or ipa (get it from maplins) then i just worked the head unit in and out and used cotton buds to clean the lip of the coil and the shaft, also make sure the little brass bearing is seated in its base as mine was coming out a bit

its now cutting fine at 75g pressure through standard 3 to 5 year vinyl, and just leaving a slight indent in the backing paper, one last thing make sure you dont get ipa in the encoder motor it will run through and cause the encoder not to work till it completely dries out, so i hope this solves your T750, T1400 or whatever summa tangential head sticking problem you have, just added that so peeps can find this thread, as i searched for ages, also if anyone has any further info on summa's please post as its better than paying 1000's of pounds or dollars to get them fixed

Alan