nolanola

https://manhattansignshop.nyc/

Hello.

We got a job to make a 24' x 12' aluminum sign (9 sheets) with vinyl on it.

It will go on a corrugated metal wall.

What is the right way to do it?

I like how aluminum pan signs look, but I believe its not possible in this case, because there should be no gaps between the panels.

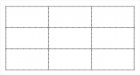

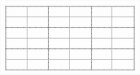

The grey lines on the attached below are 2x2 aluminum square tubing. The maxmetal sheets will be attached to the aluminum tubing to prevent it from waving (corrugated metal wall).

Is it the right way to do it?

Thank you.

We got a job to make a 24' x 12' aluminum sign (9 sheets) with vinyl on it.

It will go on a corrugated metal wall.

What is the right way to do it?

I like how aluminum pan signs look, but I believe its not possible in this case, because there should be no gaps between the panels.

The grey lines on the attached below are 2x2 aluminum square tubing. The maxmetal sheets will be attached to the aluminum tubing to prevent it from waving (corrugated metal wall).

Is it the right way to do it?

Thank you.