Kerning on type was originally designed into the sort for certain letters that needed to overlap the body of the sort to look good.

This is true.

The noun

kern and the verb

to kern are not new terms, but old ones, though the shade of meaning has changed considerably from previous centuries.

From Royal Dictionary, page 663, by Charles Fleming (1844 edition):

" To KERN, v. Among Letter-founders; to hollow out the under part of a letter, the eye of which projects beyond the body."

So,

kerning was the process of cutting a notch or mortise into the underside of a slug of type allowing the letter face, the raised portion (also called the

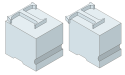

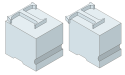

eye), to extend beyond the type slug and overlap an adjoining letter. The illustration from Wikipedia of the two letters "T" clearly shows this overlap.

By Metal_type.svg: User:Booyabazooka, User:Jensonderivative work: Rick Yorgason - Metal_type.svg, Public Domain, https://commons.wikimedia.org/w/index.php?curid=8942107

By Metal_type.svg: User:Booyabazooka, User:Jensonderivative work: Rick Yorgason - Metal_type.svg, Public Domain, https://commons.wikimedia.org/w/index.php?curid=8942107

Kerning always meant tightening the space between letters

Kerning was a way of

decreasing the spacing between two letters. It never meant adding space between letters. Greater spacing was accomplished by adding blank spacers. (In fact, fonts could be purchased that consisted of nothing more than these spacers). Kerning was an especially common practice for allowing italics to overlap, eliminating awkwardly large letter spaces created by the slant of the letters.

According to the Online Etymology Dictionary, the English noun

kern, from the 1680s, is thought to derive from french

carne, meaning "projecting angle; quill of a pen." It described the notch on the underside of a quill to create the nib, that is, the delicately pointed "business end" of the quill. In fact, just as a delicate quill point could easily be damaged, so too could the relatively weak overlap created when a letter of metal type was kerned. These projecting parts could easily break off and render the piece of type useless. Hence, kerned letters took on different design configurations in an effort to strengthen them and prevent breakage. Some projecting kerns were made beefier for strength, and foundries eventually even created built-in kerns when casting letters.

Notice in the photos of kerned italics in the page linked below how a layer of metal was left remaining behind the letterforms to reinforce them. This was one way of reinforcing the overlaps to strengthen kerned letters:

Kerned Italics

From page 18 of the book,

Type (1918), an instructional manual for apprentices:

Drawings of Kerned Italics

Note the variety of notches/mortices cut into larger sizes of type in the following link:

Large sized type kerning

Kerns, in the beginning, were painstakingly added to type slugs by hand using files, knives and gouges, but eventually, saws were developed that allowed for quicker cutting of kerns.

Today, of course, kern is used almost exclusively as a verb and simply refers to the adjusting of spacing between individual letter pairs of digital type.