-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Need Help Graphtec contour cutting length

Our rip sets up Multiple marks on the length....searches them out every 30-50 inches or so. keeps things aligned for a long print & cut!- WYLDGFI

- Post #4

- Forum: General Chit-Chat

-

-

10x40 foot banner....what matieral

Do you have a close up of the banner media that's up there?- WYLDGFI

- Post #16

- Forum: General Signmaking Topics

-

Need Help Arena Seat Covers

We're in the US...able to ship Ground to you.- WYLDGFI

- Post #2

- Forum: General Chit-Chat

-

Question Mesh Banners and wind load

The 3rd layer on mesh helps avoid a lot of headaches with rip outs. Just that extra meat for the grommets to grab around the perimeter helps a ton.- WYLDGFI

- Post #4

- Forum: General Signmaking Topics

-

Question Mesh Banners and wind load

From the printer standpoint, sounds like you are on the right track. Zips should let go before the mesh does. Hopefully the mesh has a 3 layer hem on the perimeter otherwise they're going to have tear outs at the grommets.- WYLDGFI

- Post #2

- Forum: General Signmaking Topics

-

Happy Easter Everyone!

Just wanted to wish everyone out there looking forward to Sunday a Happy Easter with family! I know to many it means different things and I wish everyone the best. Working hard today still.....and back to it again on Monday.- WYLDGFI

- Thread

- Replies: 5

- Forum: General Signmaking Topics

-

Question Life span of a print from an HP Latex 560

On our 560 we run it in 8p for standard stuff and 10p110 for vehicle decals and all of our quick, short run work. We do a majority of our big runs on the 1500's we have. Wraps always get printed 6p 110. 180, 1105EZ....etc. Whatever the client prefers mostly. Wrap on my personal boat looks...- WYLDGFI

- Post #10

- Forum: Digital Printing

-

Need Help Strange alignment issues with HP L360

balstestrat would probably know the most about that unit and why.- WYLDGFI

- Post #2

- Forum: Miscellaneous Hardware

-

Suggestions Covering Old Pylon Sign

screw that dot com...lol. Support the guys here on S101.- WYLDGFI

- Post #7

- Forum: General Chit-Chat

-

Adding "stucco" to ACM?

Avery Dennison® MPI 2631 Stucco Texture Wall Film ... - LexJethttps://www.lexjet.com › avery-dennison-mpi-2631-stu...- WYLDGFI

- Post #6

- Forum: General Signmaking Topics

-

Adding "stucco" to ACM?

what about using a perm. adhesive stucco vinyl from Avery?- WYLDGFI

- Post #3

- Forum: General Signmaking Topics

-

Need new flatbed - Advice please (NOT HP...)

Youre going to be really happy with the 2500i. We have one of those and its a workhorse! Have had some issues here and there...but nothing crazy.- WYLDGFI

- Post #16

- Forum: Flatbed Printers

-

Need new flatbed - Advice please (NOT HP...)

We have AGFA. Nice printer with LED lamps.- WYLDGFI

- Post #8

- Forum: Flatbed Printers

-

What do you consider "color matching"......?

As a printer...color matching from one printer to another can be tricky. Taken the proper time, it is feasible and should have been thought thru in this case of course. Printing on the Same Exact printer for the color matching is the scenario that should have been in place if...- WYLDGFI

- Post #14

- Forum: General Chit-Chat

-

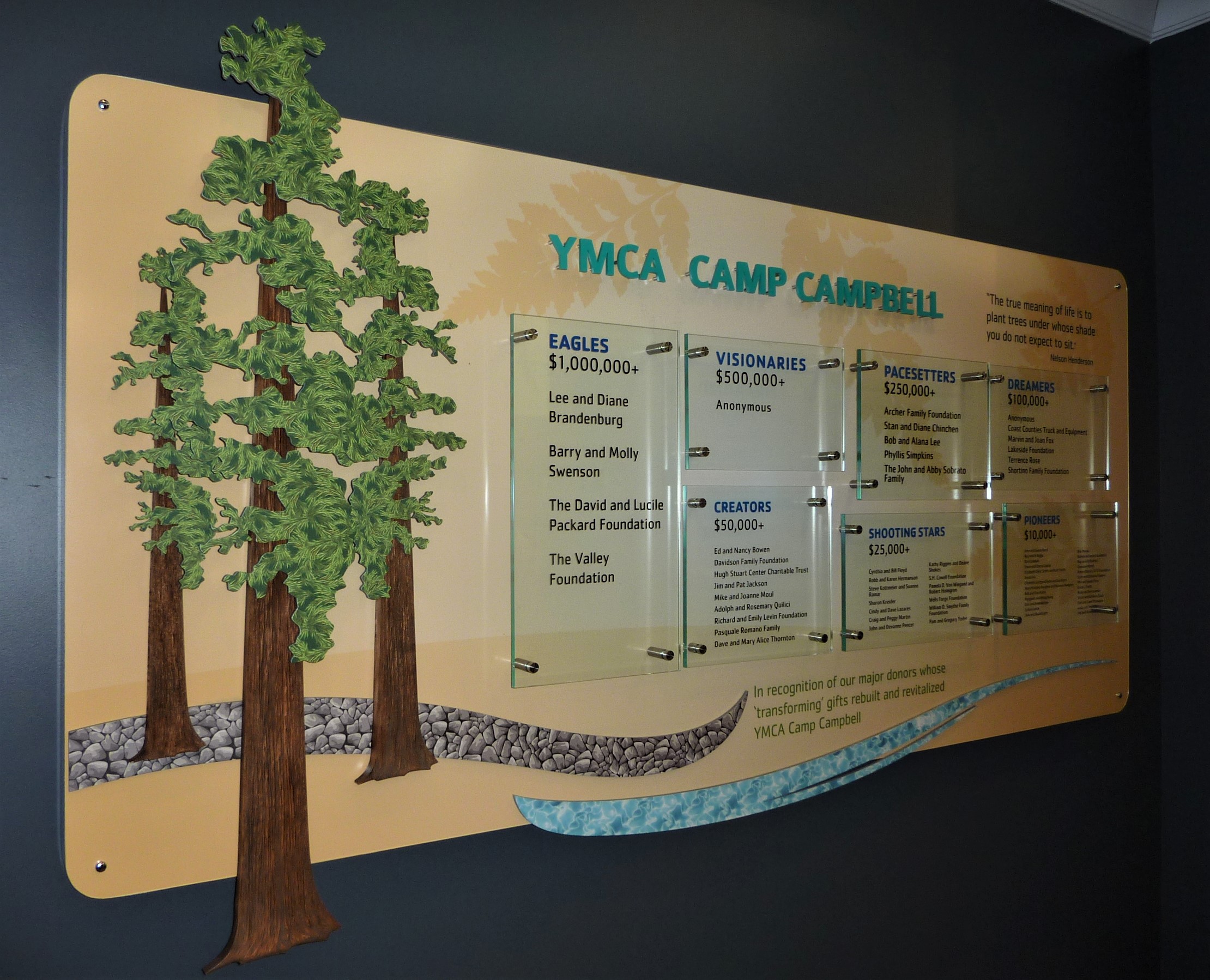

Material suggestions for donor recognition display

Acrylic isn't bad....printed UV and routered- WYLDGFI

- Post #5

- Forum: General Signmaking Topics

-

Looking for E Flute White/White Cardboard

Do you deal with a local print/offset shop? Ask them who their paper supplier is.....I know in NJ Lindemeyr is a big name around here and they stock E Flute.- WYLDGFI

- Post #2

- Forum: Product and Supplier Referrals

-

Semi-Rigid Vinyl options

You can get BeLam Econo for Sub $110 roll from N Glantz. NO UV protection in it....1.5 mil I believe. GF, BL & Oracal are the ones I would recommend....Avery is out there and Im sure Bigfish here has a material in the 4mil thickness. He's probably got a lam as well. -

-

-

Laminator Suggestion

If you were local...I have a used one I have sitting here.- WYLDGFI

- Post #3

- Forum: General Signmaking Topics