-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

HP 700W profile creation and Flexi

I noticed something today when I created a 3 layer sandwich profile. When I go to select the newly created profile in Flexi it created 2 of them with the same name except one of them has "side B" Whats the deal with "Side B" profile and when should I be using it? So say im setting up a layered...- DChorbowski

- Thread

- Replies: 5

- Forum: HP Latex Printer

-

-

ISO 60in inexpensive bond paper with 3in core

Tubelite was able to source some for us. There is no branding on the box but its on a 3" core and 20lb bond.- DChorbowski

- Post #4

- Forum: Product and Supplier Referrals

-

Blockout vinyl?

For what its worth, we ended up using the General formulations has an glossy option with their GF 218 Windowmark. It printed beautifully on our HP 700W. Thanks for everyones help.- DChorbowski

- Post #9

- Forum: General Signmaking Topics

-

HP Latex 700/800W Ink shortage?

Whats the expiration dates?- DChorbowski

- Post #3

- Forum: HP Latex Printer

-

HP Latex 700/800W Ink shortage?

Is anyone else experiencing issues with ink not being in stock? Or is this just a regional thing? Im in South Florida.- DChorbowski

- Thread

- Replies: 3

- Forum: HP Latex Printer

-

Printer Problems! Is something stuck?

Yikes, i didnt think those little rubber parts could separate from caps. Good to know!- DChorbowski

- Post #6

- Forum: HP Latex Printer

-

Blockout vinyl?

Only UV? Thats unfortunate as we are only running a HP Latex at this time. Thanks though!- DChorbowski

- Post #6

- Forum: General Signmaking Topics

-

Blockout vinyl?

It does not, I just need it to cover up backlit panels temporarily with new printed graphics. Do you know the product number for this Drytac film?- DChorbowski

- Post #3

- Forum: General Signmaking Topics

-

Blockout vinyl?

I have a huge project needing alot of blockout vinyl. Our standard blockout that we use is the 3M 3635-20B, but it appears that our vendors are completely out of stock and having a tough time getting any 3M blockout film to me in my needed timeframe. I am looking for alternatives for...- DChorbowski

- Thread

- Replies: 8

- Forum: General Signmaking Topics

-

Translucent vinyl lifting around panel edges

It appears the retainer angle may be causing it as it looks like its being pulled in one direction. Perhaps its due to thermal expansion and contraction of the plastic vs aluminum? Or when they cranked down the screws it pulled on the vinyl?- DChorbowski

- Post #2

- Forum: General Chit-Chat

-

Latex Printer in apartment?

You need to consider the power requirements. The 365 needs (2) 240v lines like the 700W does, correct? Also consider how you are going to get it into the room you would like, as its a big fat and awkward machine to get around tight corners and god forbid stairs.- DChorbowski

- Post #3

- Forum: General Signmaking Topics

-

Installer needed in Odenton, MD.

Small world, I actually used to live just outside of Odenton MD. There is a fastsigns there that is of a decent size they should be able to help. Fastsigns Address: 1701 Midway Rd, Odenton, MD 21113 Phone: (443) 419-7240- DChorbowski

- Post #3

- Forum: Member to Member Classifieds • Help Wanted

-

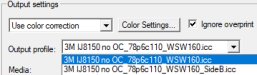

Prints on clear acrylic

Glad to hear. I love 3M's 8150 for window graphics, but when I dont need crystal clear such as on backlit signage, I use IJ3630-114. 95% of the signage we produce are intended to be long-term/permanent. I personally havnt tried the 40c-10R clear yet, but i do run thru about 15 rolls of the...- DChorbowski

- Post #27

- Forum: General Signmaking Topics

-

Prints on clear acrylic

I ALWAYS start with it attached to the takeup reel. I generally print on 6 pass 8 color when no white ink is needed, I start at 194 degrees, may go down a degree or two. Vacuum is set to 20 and no interpass delay but will sometimes adjust that up to 300-600 if the ink does not seem to be...- DChorbowski

- Post #25

- Forum: General Signmaking Topics

-

10 year guarantee clear laminate?

1170C is the clear. I am not sure if its graffiti resistant though.- DChorbowski

- Post #7

- Forum: General Signmaking Topics

-

10 year guarantee clear laminate?

Look into 3M 1170- DChorbowski

- Post #2

- Forum: General Signmaking Topics

-

Need Help Latex printer Vs Optical Clear

Can you clarify this statement? How is this done?- DChorbowski

- Post #3

- Forum: Digital Printing

-

The non Laminator, Lamination

I use our rollsroller(s) every day for lamination. Our tables are the 16' long version. How we do it is we fully lay our print out on the table and then place the desired amount of laminate on top. we leave about 8-10" extra on one end of both the print and the laminate. This extra amount...- DChorbowski

- Post #3

- Forum: General Chit-Chat

-

Backlit Vinyl Bubbling After 3 Years

Lexan can absorb and retain moisture, and then when it heats up it has nowhere to go due to the vinyl. Ive never seen this happen after years, but I have seen it happen within hours of application. Is there any chance you can check the inside of the can and see if theres moisture in there...- DChorbowski

- Post #8

- Forum: General Signmaking Topics

-

FC-8600 pinch roller question

From what i remember the left and right rollers have an extra piece on them to let the machine know where the cutting boundaries are. It should look like a little metal tab on the rear that sticks up.- DChorbowski

- Post #3

- Forum: Graphtec