-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

10mm coroplast cut tool?

- Thread starter MHester

- Start date

MHester

New Member

I have certainly thought of outsourcing, of course. But I always love a challengejust sub the job to signs365....

MHester

New Member

Ha, do they even make those any more?Cutawl. The sovereign solution for this sort of work.

FireSprint.com

Trade Only Screen & Digital Sign Printing

We do contour cut 10mm all the time if you need help. We can also screen print 10mm corrugated plastic for 1-3 color jobs of 50pcs or more to save some $$.

https://www.firesprint.com/yard-signs-10mm-heavy-duty-digitally-printed/

https://www.firesprint.com/yard-signs-screen-printed/

https://www.firesprint.com/yard-signs-10mm-heavy-duty-digitally-printed/

https://www.firesprint.com/yard-signs-screen-printed/

rjssigns

Active Member

Ha, do they even make those any more?

https://www.ameriken.com/products/die-shop-equipment/die-shop-equipment-cutawl-saws/

Mark Mooney

Creative Brand Strategist

Has anyone ever used a rotary saw like this one? Would it work, or wold it just tear up the coroplast?

I don't know if you ever tried the rotary saw or not, but I just bought one for the exact same purpose of cutting a custom shape with curves out of 10MM coroplast. I only have 2 of the same cutouts to do, so this tool seemed like the fastest and cleanest way. It's supposed to be delivered in a couple days, I'll repost here and let everyone know how it goes.

MHester

New Member

I ended up using a jig saw with a fine blade. Does well for cutting the curves, but had to sand away the fringes afterwards. It's definitely my go-to tool now.I don't know if you ever tried the rotary saw or not, but I just bought one for the exact same purpose of cutting a custom shape with curves out of 10MM coroplast. I only have 2 of the same cutouts to do, so this tool seemed like the fastest and cleanest way. It's supposed to be delivered in a couple days, I'll repost here and let everyone know how it goes.

Attachments

mhester

do you mind if i ask what you charge for those?

we do a large (32" x 48") coffee cup with color graohic logo and 5 lines of text for a couple clients. we charge between $75- $95 print and stick, custom shape and laminated, dependong on quantity (typically <20)

are we charging too much, not enough? (the ship has already sailed for this group of clients, now that we set a price...)

do you mind if i ask what you charge for those?

we do a large (32" x 48") coffee cup with color graohic logo and 5 lines of text for a couple clients. we charge between $75- $95 print and stick, custom shape and laminated, dependong on quantity (typically <20)

are we charging too much, not enough? (the ship has already sailed for this group of clients, now that we set a price...)

MHester

New Member

mhester

do you mind if i ask what you charge for those?

we do a large (32" x 48") coffee cup with color graohic logo and 5 lines of text for a couple clients. we charge between $75- $95 print and stick, custom shape and laminated, depending on quantity (typically <20)

are we charging too much, not enough? (the ship has already sailed for this group of clients, now that we set a price...)

Ours are about 36" X 58"-ish (depending on the graphic) and are 1 sided. We design, print on vinyl, laminate, then mount on coro and hand cut. We charge $135 for the insert, and antenna sign base is sold separately. These are normally only 1-2 in quantity. Wish we had a flat bed printer and cnc cutter to speed up the process, but we do fewer than a dozen of these per year.

Mark Mooney

Creative Brand Strategist

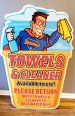

I also ended up using my 17 year old jigsaw with a fine-tooth blade... I sent the rotary saw back, it was too hard to control cutting through the thick plastic ribs of the 10mm coroplast, a machine controlling it would work, thus a CNC cutter. I had a lot of straight lines, sharp angles and curves to cut out, and the jigsaw did an incredibly good job. I did have to sand down the edges of the cuts in some places because plastic naturally wants to gather and "curl up" in lots of nooks and crannies from where it gets heated up and melted during cutting. So, because of that melting plastic effect, I found the faster I cut the cleaner the cut. But, that obviously means more room for error in cutting accuracy. I felt like I found a balance between speed and accuracy that gave me the best result with the least amount of sanding. This being my first custom contour cut 10mm coroplast, I was pleasantly surprised I could mount the laminated/printed vinyl on the substrate before cutting and the edges of the vinyl came out very clean. I think it definitely helps leaving a white margin around the entire edge of the vinyl to blend with the white of the cut coroplast. Here's a photo of the finished signs (2) at 38"x55", it's for a car wash.I ended up using a jig saw with a fine blade. Does well for cutting the curves, but had to sand away the fringes afterwards. It's definitely my go-to tool now.

Mine were close to the same size and I charged $125 each, but that was after my customer negotiated down from my original quote of $180 per. Their old vendor did something similar for $95 (without metal stand), and I'd never done anything like this one, so wasn't sure what the labor would be. $125 each ended up being well worth it once I understood the best way to cut them by hand. I however, printed these on adhesive vinyl, laminated, mounted on 10mm coro, then hand cut. A CNC cutter would definitely be nice, but if you're a noob to the industry, they can be pricey. If you did a lot of these types of signs, a CNC cutter would be a necessity.Ours are about 36" X 58"-ish (depending on the graphic) and are 1 sided. We design, print on vinyl, laminate, then mount on coro and hand cut. We charge $135 for the insert, and antenna sign base is sold separately. These are normally only 1-2 in quantity. Wish we had a flat bed printer and cnc cutter to speed up the process, but we do fewer than a dozen of these per year.

For me no, I charged an hour ($100) for the design in addition to $125 per physical sign produced. So, I charged $350 total for the two signs. Nice thing is, next time they want another one for a new location, it'll be even faster to produce now I know how, and I'm totally fine with $125 per sign.Nice. Is your design time included in those prices or do they supply you with finished artwork files, ready to print ??

Attachments

Last edited:

MHester

New Member

That includes our design time, unless there are multiple edits, etc; then we start charging $125 per hour (to to dissuade folks from going overtime on edits) We normally include up to 1 hour of design time with our price.Nice. Is your design time included in those prices or do they supply you with finished artwork files, ready to print ??

MHester

New Member

Lucky dog, getting a CNC router. Wish we had the budget for one. Have fun with it!MHester

not sure if my plan is a good one. we are getting a 48" x 96" bobcnc to automate the cutting process

fortunately, i am the only one on staff who really sucks at hand cutting

(it's really handy to have me around when equipment malfunctions, though)

d fleming

New Member

I've done quite a bit of 10 mil with print applied. I cover with transfer tape to avoid damaging print and knock it out with a jigsaw and fine blade. A cutawl would be great too. I use a sanding block to quickly knock burrs off and peel tape. If you are not doing a lot of this kind of work jig or cutawl should suffice. I have been using these at home for about 8 years now.

Attachments

graphicsottawa

a.k.a. Phaedra

I cut some yesterday using a Bosch Colt router with a template bit following a piece of Alupanel as a guide. This worked pretty well with minimal fuzz left to clean. I had a print on the coro, and that was covered with a layer of prespacing tape to protect the print. Of course, I checked this thread first to see what other people have tried

Howdy, new here. But I have to say that is a pretty nice tool. thank you for sharing.The only thing that I know of is this handheld CNC router, it's not as large of a investment as a CNC table & you can store it away.

At around $2500 it still might not be worth it though.

bob

It's better to have two hands than one glove.

You're printing, what does it matter how many lines of text? Also, since you're starting with a 32x48 substrate, applying a print, and cutting something out of it why does the price vary by $20.00? Don't say cut complexity, is shouldn't matter. Set a price, a single price, that will cover the average situation. Then in the main you'll be making what you want and on the extremities [really simple or hideously complex] you'll win some and lose some but it will average out to close enough to your price that it won't matter.mhester

do you mind if i ask what you charge for those?

we do a large (32" x 48") coffee cup with color graohic logo and 5 lines of text for a couple clients. we charge between $75- $95 print and stick, custom shape and laminated, dependong on quantity (typically <20)

are we charging too much, not enough? (the ship has already sailed for this group of clients, now that we set a price...)