signmeup

New Member

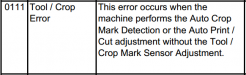

I can't get my SP54V to cut to crop marks. I don't think the issue is it can't find the marks. It doesn't even look for the marks... you can’t even set the crop marks manually and have it follow them. It just sets service call 0111 as soon as click "print".

I installed a new crop mark sensor but no joy. The sensor works to calibrate the voltage test. I set it to 2.6v which is within specs of 2.5 + -.2v. If I move the carriage the voltage changes as the eye is moved from the black square to the white vinyl.

Maybe a software issue? Maybe I’m not manually setting the marks correctly? The only way it will cut anything is if “crop marks” are not turned on in Versaworks.

Adrian

I installed a new crop mark sensor but no joy. The sensor works to calibrate the voltage test. I set it to 2.6v which is within specs of 2.5 + -.2v. If I move the carriage the voltage changes as the eye is moved from the black square to the white vinyl.

Maybe a software issue? Maybe I’m not manually setting the marks correctly? The only way it will cut anything is if “crop marks” are not turned on in Versaworks.

Adrian