Gene@mpls

New Member

This has been a work in progress- but I think is is done and I am

satisfied. Not only am I cheeep- but I like to customize things to my

tastes. The winder is a rotisserie motor (50 or 100$) with a homebrew

brass adapter to turn a closet rod with various plastic plumbing fittings

to get to the right size to slip a 3" core on. The plastic has some slip

when fit to the rod and coro strips screwed to the plastic has tension/slip

to the core. To load a core you lift the left side of the rod and slip it on-

same to unload- to transfer the core to a wall mounted post leading to

a 12ft table and then to the laminator. I don't think this is common- but...

I also like that I don't have to stoop, as my stooper does not work as it

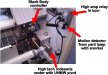

used to. The winder is turned on/off by a motion detector/relay that also

runs the IR heater. The snorkel picks up the print carriage and triggers

the winder and IR- and shuts off after no motion for 4-5 min. This has not been a problem as the winder will slip for this interval and the IR does not overheat the vinyl before turning off.

The IR I bought is an add-on unit meant to add to an existing heater

on a stand- cheaper and I didn't want the stand. I tried it on top of the

vinyl but it is very clumsy so switched to the bottom with a stainless

'grill' to keep the vinyl off until it is attached to the winder. IR heats from

the inside out so I get good drying. When the vinyl is attached to the

winder the vinyl is pulled taut- the distance can be adjusted with the

large wing nuts which come with the unit.

I am sure a lot of purists are puking on their shoes but it works for me

and has made me a millionaire (joke- but multi-thousandaire). Gene

satisfied. Not only am I cheeep- but I like to customize things to my

tastes. The winder is a rotisserie motor (50 or 100$) with a homebrew

brass adapter to turn a closet rod with various plastic plumbing fittings

to get to the right size to slip a 3" core on. The plastic has some slip

when fit to the rod and coro strips screwed to the plastic has tension/slip

to the core. To load a core you lift the left side of the rod and slip it on-

same to unload- to transfer the core to a wall mounted post leading to

a 12ft table and then to the laminator. I don't think this is common- but...

I also like that I don't have to stoop, as my stooper does not work as it

used to. The winder is turned on/off by a motion detector/relay that also

runs the IR heater. The snorkel picks up the print carriage and triggers

the winder and IR- and shuts off after no motion for 4-5 min. This has not been a problem as the winder will slip for this interval and the IR does not overheat the vinyl before turning off.

The IR I bought is an add-on unit meant to add to an existing heater

on a stand- cheaper and I didn't want the stand. I tried it on top of the

vinyl but it is very clumsy so switched to the bottom with a stainless

'grill' to keep the vinyl off until it is attached to the winder. IR heats from

the inside out so I get good drying. When the vinyl is attached to the

winder the vinyl is pulled taut- the distance can be adjusted with the

large wing nuts which come with the unit.

I am sure a lot of purists are puking on their shoes but it works for me

and has made me a millionaire (joke- but multi-thousandaire). Gene

Need to post a drawing for those of us that want to DIY. I take it the motion sensor detects movement of the printhead?

Need to post a drawing for those of us that want to DIY. I take it the motion sensor detects movement of the printhead? :ROFLMAO: Franken-heater...too funny.

:ROFLMAO: Franken-heater...too funny.