jiarby

New Member

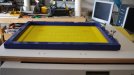

Built a home-made one color press (using the loosest definition of the word) to screen print 18x24 bandit signs...

$10 A simple 30x40 melamine base from Home Depot

$22 A set of Jiffy Clamps

$0 Some scrap Rowmark 1/8 spacers (to build up off contact)

$0 Some more Rowmark to use as a guid to place the coro in same place every time

$31 A 230 mesh 23x31 screen

$30 Squeegee

Total, about $100

I am planning to use some transfer rite heavy duty tape on the pallet (sticky side up, then use masking tape to hold it to the pallet) to hold down the coros (we do this already when mounting a bunch with the big squeegee)

I thought this would be a good way to do a couple of those bandit sign jobs we get calls on now & then... If it works out I have my eye on a Workhorse 4-1 with a vacuum pallet ($1500) or a used Lawson Mustang ($5K -$7K)

The screen place here in Tempe sold me some "ColorFX" ink and some retarder... no idea if that is good or not. Tubelite is across town, O think thet carry Ulano & Nazdar

Note...

This is not for tshirts, just coro signs, maybe some poly coated cardboard.

$10 A simple 30x40 melamine base from Home Depot

$22 A set of Jiffy Clamps

$0 Some scrap Rowmark 1/8 spacers (to build up off contact)

$0 Some more Rowmark to use as a guid to place the coro in same place every time

$31 A 230 mesh 23x31 screen

$30 Squeegee

Total, about $100

I am planning to use some transfer rite heavy duty tape on the pallet (sticky side up, then use masking tape to hold it to the pallet) to hold down the coros (we do this already when mounting a bunch with the big squeegee)

I thought this would be a good way to do a couple of those bandit sign jobs we get calls on now & then... If it works out I have my eye on a Workhorse 4-1 with a vacuum pallet ($1500) or a used Lawson Mustang ($5K -$7K)

The screen place here in Tempe sold me some "ColorFX" ink and some retarder... no idea if that is good or not. Tubelite is across town, O think thet carry Ulano & Nazdar

Note...

This is not for tshirts, just coro signs, maybe some poly coated cardboard.