Stacey K

I like making signs

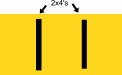

Hi All - the baseball club ordered a bunch of signs last year and 3 signs three cracked in half. I'm pretty sure I had used the Bebond Premium 2 sided 3mm, - unless I used the economy? I rarely have any of that and avoid using it for these kinds of signs so I feel that's unlikely. That's the only thing I can think of. I've done probably 30 other signs for different fields etc. and never once had an issue. I do know other people install them with 2 vertical 2x4's like 1/3 in the middle of the sign and I see they used just bolts and a 2x4 on top.

I think I should drive over there and see if these are the only 3 in this particular area. Other signs I made them did not break. The other day we had gusts up to 70.

I think I should drive over there and see if these are the only 3 in this particular area. Other signs I made them did not break. The other day we had gusts up to 70.