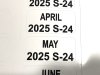

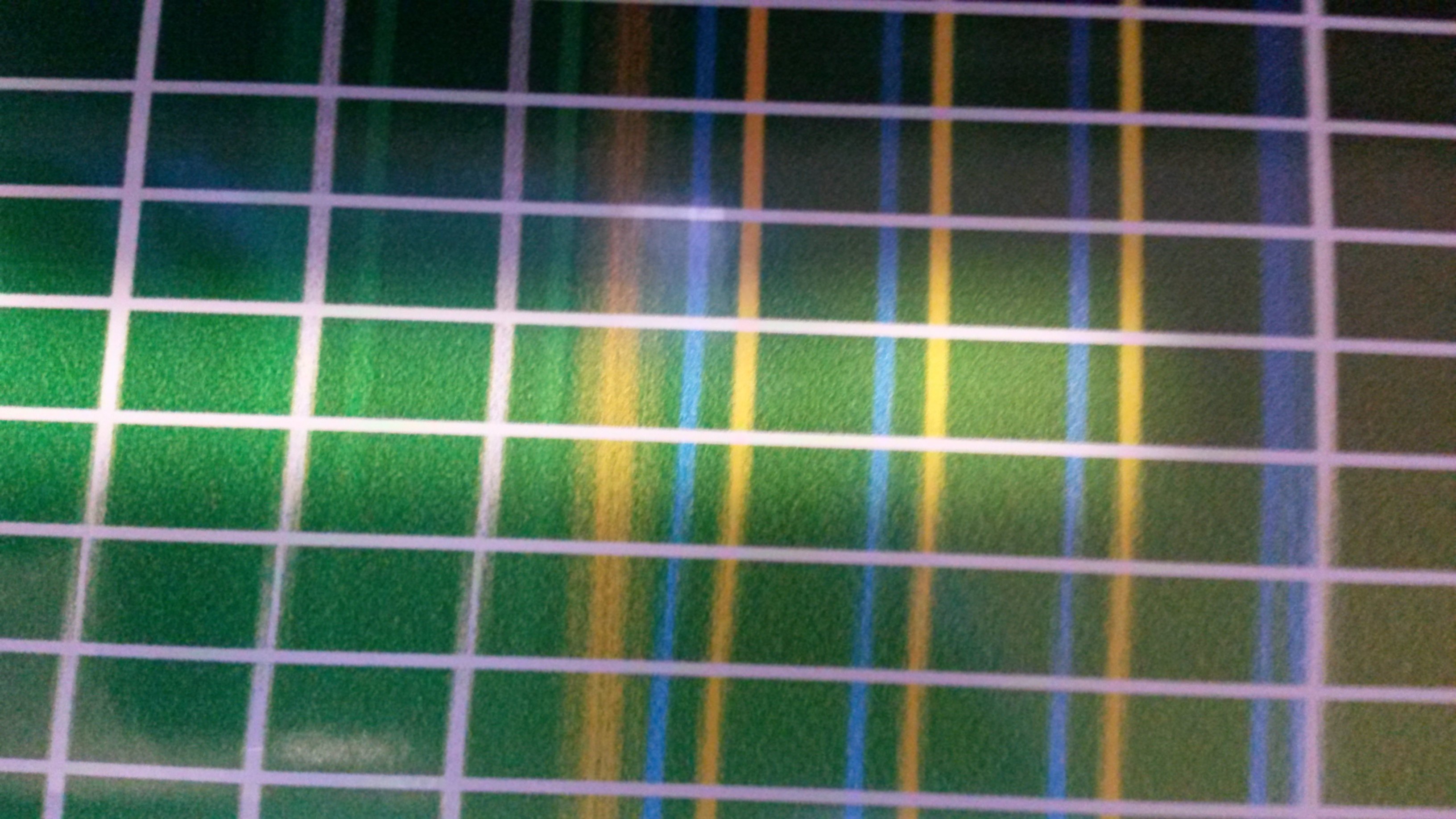

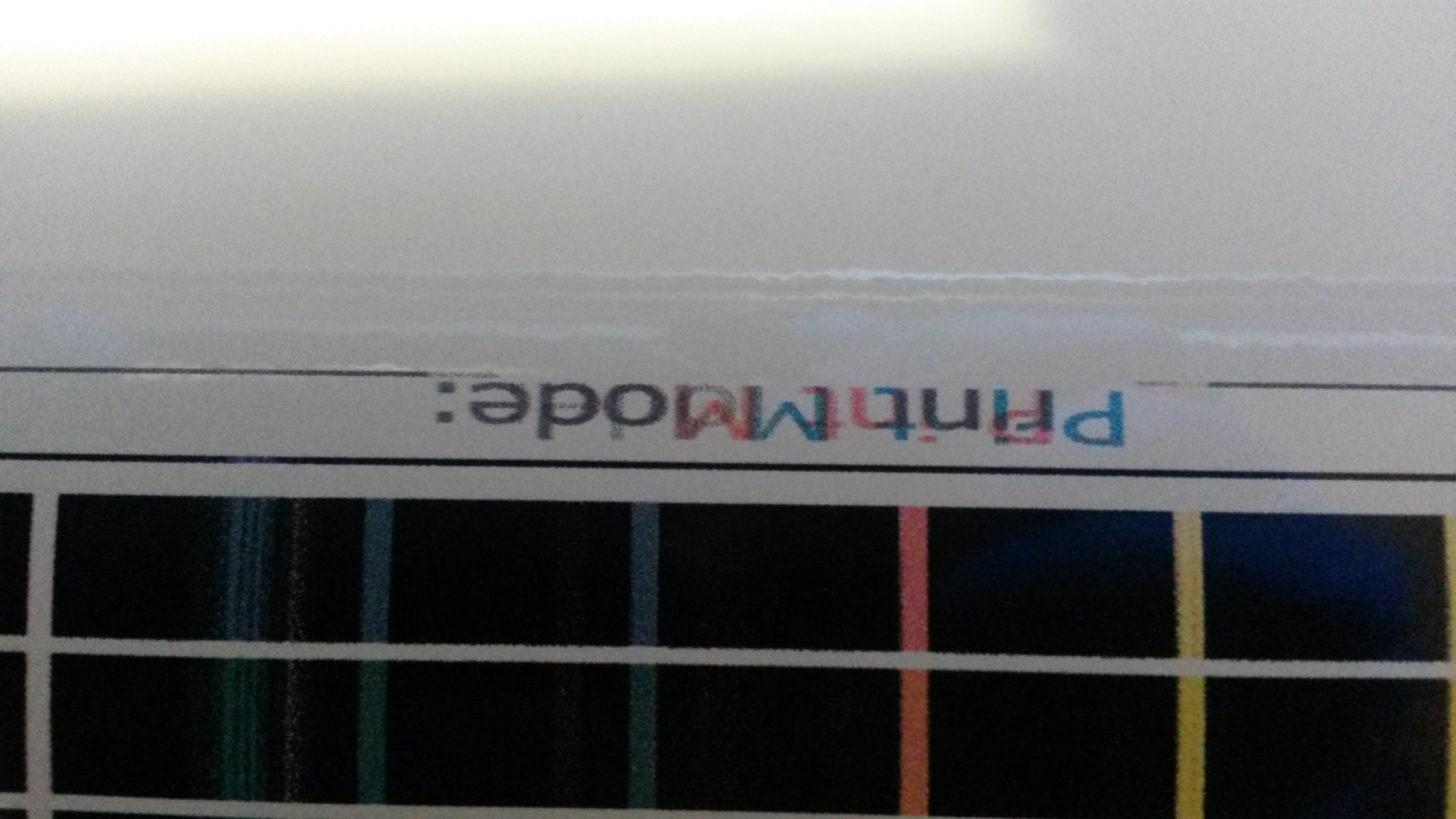

I am having trouble getting a good print. Here are photos from a 48" x 16" Pantone chart I printed as a test. The left and right edges are wavy and distorted. There is a row about a foot in that things get scrambled along. The #17 is black and it prints that plus a ghost #17 1/4" away in red. The swatches are all scrambled and goofy running down the print in that one area. The lettering at the bottom of that area is

also all scrambled.

Any ideas?

also all scrambled.

Any ideas?

Attachments

Last edited: