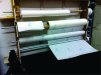

I'm not sure what has changed, but latedly, everything I apply application tape to that is 24" up to 30" wide, I get wrinkles in my application tape right at the start. I use a 32" BS to apply my tape and I use R Tape Conform.

How I apply...... I lay my graphic on my flat work surface...... I grab my roll of application tape ( usually 30" )..... I pull off a few inches from the roll so that I have some tape to stick to my table top.... now, this is were I do notice that some of the wrinkles get in the tape. I must not be pulling my tag end off evenly, but I've tried it several ways and can not find a true way to do it. So I will waste a foot or more trying to get it so that the tape starts running smooth without any bubbles or wrinkles. The wrinkles are always on the outer 2 edges, which makes me believe that it's the way I'm starting my tag end from the roll.....maybe I'm stretching it or something????

Does anybody have any tips for starting the tape process using a Big Squeegee?

How I apply...... I lay my graphic on my flat work surface...... I grab my roll of application tape ( usually 30" )..... I pull off a few inches from the roll so that I have some tape to stick to my table top.... now, this is were I do notice that some of the wrinkles get in the tape. I must not be pulling my tag end off evenly, but I've tried it several ways and can not find a true way to do it. So I will waste a foot or more trying to get it so that the tape starts running smooth without any bubbles or wrinkles. The wrinkles are always on the outer 2 edges, which makes me believe that it's the way I'm starting my tag end from the roll.....maybe I'm stretching it or something????

Does anybody have any tips for starting the tape process using a Big Squeegee?