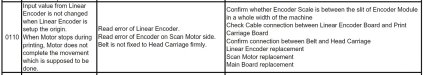

Was printing some vinyl and the carriage caught on the media clamp (broke it) and then gave me scan motor error 0010 0010. Went after resetting it it gave me service call 0110.

I have cleaned the encoder strip, put the carriage over the media and turned it on in service mode to verify it rolls back to the home position. Ran a linear calibration and sensor check and reset the limit initialization. None of that made a difference. It will turn on and immediately clunks and gives me one of the two error codes again. Carriage does not move upon start up unless it's left over the media area and returns.

Looking for any ideas on what you would do to resolve this issue. I've seen that I could need a new encoder strip and sensor but wanted to get opinions before buying anything.

I have cleaned the encoder strip, put the carriage over the media and turned it on in service mode to verify it rolls back to the home position. Ran a linear calibration and sensor check and reset the limit initialization. None of that made a difference. It will turn on and immediately clunks and gives me one of the two error codes again. Carriage does not move upon start up unless it's left over the media area and returns.

Looking for any ideas on what you would do to resolve this issue. I've seen that I could need a new encoder strip and sensor but wanted to get opinions before buying anything.