-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Need Help BUBBLES! Need clear answers on vinyl application

1. Use a better vinyl. CAST. 751 if you wish to use the Oracal product. Look into vinyl like 3M 180mC. Use the technology that is available to you! 2. Dry Dry Dry! If you really look the manufacturers do not recommended wet applications 3. Make sure your squeege is sharp. You can sharpen by...- Modern Ink Signs

- Post #2

- Forum: Installation Equipment & Techniques

-

-

How do you work with big companies?

Your lack of planning or “emergency” is not mine..... Once you jump through that hoop you will always have to jump through that hoop. Set your cutoff dates for production and that is it. Why should your other clients not get the same treatment? Big or small they all spend their money with you...- Modern Ink Signs

- Post #3

- Forum: Business Management

-

Help... Can you apply vinyl to this type of brick?

1. Yes you can install on a wall like that. You don’t need to paint or grind or anything like that. Maybe pressure wash but definitely a cleaning with a hard bristled brush. Then you need the proper foam roller and heat gun that can get to 1000 degrees. Yes that is correct 1000!!! 2. 180 is...- Modern Ink Signs

- Post #18

- Forum: General Signmaking Topics

-

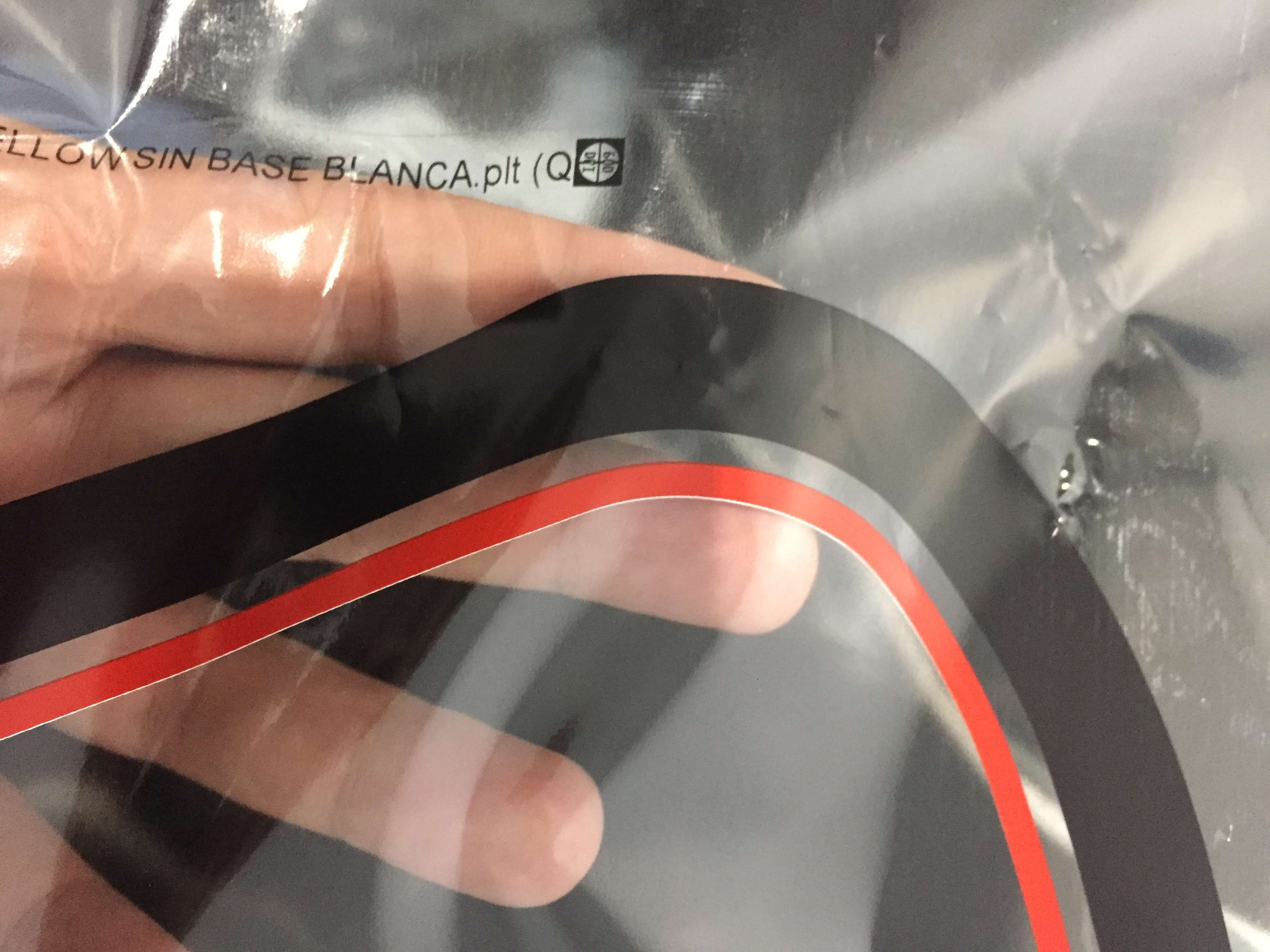

Printable vinyl for glass

That is a calandered vinyl. Cast will give you minimal shrinking but most have gray adhesive. Look at your product bulletins for adhesive type- Modern Ink Signs

- Post #3

- Forum: Digital Printing

-

Need Help Am I crazy, or can this not be printed as is?

educate your client We can print them and this is the way they will look and the cost is $x.xx Or We can send them out to be done and the cost is $x.xx Pros and cons for each are...... Not to mention are these for outdoor? Neon does not last outdoors. I’d say 6 months at best- Modern Ink Signs

- Post #15

- Forum: Newbie Forum

-

yard flags

Make sure you look at the poles. Most are aluminum and bend under wind load. I order mine through Creative Banner. You pay a bit more but the poles are much better. Educate yourself and you client. Let them make the decision on how they want to spend their money.- Modern Ink Signs

- Post #4

- Forum: Product and Supplier Referrals

-

Need Help Sherwin Williams ProMar 200 Zero VOC Interior Latex paint - no stick!

What have you tested? Info please- Modern Ink Signs

- Post #2

- Forum: Vinyl

-

Need Help Best Way to do a Float Mount

We make cleats from pvc. We have various thickness make up (3mm, 6mm, etc) We adhere the cleats and spacers to the back of the sign. Add a couple of small pieces of tape to the part of the clear that goes on the wall. Installation Tape the cleat together (just enough to hold together), remove...- Modern Ink Signs

- Post #3

- Forum: Installation Equipment & Techniques

-

2'x17' vinyl install

Either method is fine. Just depends on which you are more comfortable with. I would transfer tape it. If you are in the sun this will help maintain stability while you install and also helps keep it from skewing or stretching- Modern Ink Signs

- Post #4

- Forum: Installation Equipment & Techniques

-

How can we get started with making channel signs?

We use World Wide Signs for making our channel letters. I know their approximate cost for this so I can give the client an approximation on cost based on initial consult. We do the following: Get a deposit Do the design/proof/approval Finalize cost Secure sign permit (as needed) Have them...- Modern Ink Signs

- Post #2

- Forum: General Signmaking Topics

-

Discussion Investor

I personally would stay away from that. I’ve had people ask the same thing. No thanks. Specially a friend. Something goes wrong, there goes the friendship. Same goes for hiring friends or family. Nope! Have him buy the trucks and start his own company. Then sub out your work to him. If...- Modern Ink Signs

- Post #7

- Forum: Sales, Marketing, Pricing Etc.

-

how much for a gerber cartridge

In my opinion, yes they are just as easy to use. You do need an empty cartridge to cut open on one side (side that faces up in the machine) You pop out the used foil Transfer the empty core Insert new foil Super simple. I use Gerber only if needed due to a specific color I get mine from...- Modern Ink Signs

- Post #6

- Forum: Gerber Omega, Graphix Advantage & MacImprint

-

Replacing a print head on a GS6000 myself?

I’m going to guess that you will also need the diagnostic program that they use to install the print head. I had 1 done last week and the tech was plugged into the machine when doing his calibrations. Just a guess... We had to call Epson and then in turn they call out the tech. If I...- Modern Ink Signs

- Post #3

- Forum: Epson

-

Perforated graphic coming loose

Now you know how NOT to install perf.....- Modern Ink Signs

- Post #6

- Forum: General Signmaking Topics

-

Yes, people are really like that...

And that’s why we don’t give out verbal quotes I’ll send them and then get a signed copy. Absolutely no ambiguity.- Modern Ink Signs

- Post #9

- Forum: General Chit-Chat

-

Oracal

We use 651 for Gerber Edge decals and some cut vinyl We use 751 for outdoor/long term projects. For vehicles we are using 3M 180mC Oracal is a good product in my option and I have not had any problems- Modern Ink Signs

- Post #12

- Forum: Vinyl

-

Need Help Can Window Perf used for for a windshield banner?

:dog42:- Modern Ink Signs

- Post #12

- Forum: Digital Printing

-

Problem with Omega design

You can also use the spectratone full option Red top White bottom Then select Shrink base and enter in the amount to reduce the white by.- Modern Ink Signs

- Post #10

- Forum: Gerber

-

What vinyl should I use?

AMS..... To each his own. I choose not to use calandered vinyl on vehicles. I’m not saying it is “wrong”, just my business model.- Modern Ink Signs

- Post #11

- Forum: Vehicle Graphics

-

What vinyl should I use?

Simple answer. CAST! In the end it is my name on the project and I’m never going to use a calandered vinyl in vehicles. Period. The cost difference is minimal is projects like this. I personally like the 3M 180mC vinyl or 7125. The mC reduces install times. So in the end I pay more for...- Modern Ink Signs

- Post #9

- Forum: Vehicle Graphics