-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

More automated & faster cutting

I don't have any experience with Vision CNC.- SignProPlus-Alex

- Post #5

- Forum: CNC Routers & Engravers

-

-

Anyone here build their own CNC?

Here is picture of my cnc. Steel frame. Aluminum gantry. Nema 34 motors wit 4:1 reduction. Rack and pinion. 25mm NSK rails. 1.5 Kw water cooled spindle. 50x100 inches cutting pocket. 4 zones vacuum hold down. Mach3 with 210 gecko drives. I can cut 1/2 PVC in one pass at 250 ipm. It is not that...- SignProPlus-Alex

- Post #12

- Forum: CNC Routers & Engravers

-

Using Pvc for hanging sign

I make all of my hanging sign out of two pieces. I cut a 5/16 grove in the back of the signs and embed 1/4 steel rod bent to a shape of horseshoe with ends bend to eyelet . I use pins and epoxy to join two panel together.- SignProPlus-Alex

- Post #5

- Forum: Materials

-

Using Pvc for hanging sign

I would go with 1 inch. And make sure you treat both sides the same. Same amount of paint or same print.- SignProPlus-Alex

- Post #2

- Forum: Materials

-

What type of vinyl is this on these sign panels?

It could be white lexan. Yellowed over time with black vinyl on top. Bottom piece still new.- SignProPlus-Alex

- Post #11

- Forum: Electric Signs & Channel Letters

-

web store

Does anybody using web2print on there web site or something similar?- SignProPlus-Alex

- Thread

- Replies: 1

- Forum: Sales, Marketing, Pricing Etc.

-

Chipped ink when routing

Single flute or double flute, upcut or downcut?- SignProPlus-Alex

- Post #4

- Forum: Flatbed Printers

-

Chipped ink when routing

Did you try changing direction of the cut? Climb vs. Conventional. What kind of cutter do you using?- SignProPlus-Alex

- Post #2

- Forum: Flatbed Printers

-

More automated & faster cutting

If you are looking for comerrtial print and contour cut solution it is more than 15K . AXYZ, Vision, Multicam has one. Adding crop mark recognition cost about $7k on top of the price of the cnc. I do custom cut ACM with my cnc router. You just print crop marks and align cnc tool path to your print.- SignProPlus-Alex

- Post #3

- Forum: CNC Routers & Engravers

-

Anyone here build their own CNC?

I build my own. Pm if you have any questions.- SignProPlus-Alex

- Post #3

- Forum: CNC Routers & Engravers

-

Stock Acrylic or Glass Shaped Blanks

What is high cost? Do you want quote to route them? I stock 1/8 clear.- SignProPlus-Alex

- Post #4

- Forum: Materials

-

Small sandblasted signs with colors

Just for fun of it. Lets make a same sign in different sign making methods and put some pictures for a public display 1- Digital print 2- Hand painted 3- Laser etched wood 4- Etched glass 5- CNC routed 6- Sandblasted I will do CNC routed.- SignProPlus-Alex

- Post #17

- Forum: Product and Supplier Referrals

-

Small sandblasted signs with colors

Let me know if you want to go CNC routed way. I am MM.- SignProPlus-Alex

- Post #7

- Forum: Product and Supplier Referrals

-

Issue cutting ACM on Kongsberg i-XL24

I am cutting 3mm ACM single pass with .125 single flute at 125 inch/min 12000-15000 rpm.- SignProPlus-Alex

- Post #3

- Forum: CNC Routers & Engravers

-

Dimensional sign.

Extira, PVC, and HDU. Mathews paint and PPG water based acrylic.- SignProPlus-Alex

- Thread

- Replies: 5

- Forum: Portfolio Board

-

Lets talk about cheap... i mean CHEAP

I don't know about reflective but regular 10 x 40 billboard banner is $140 full color. Source from local billboard company.- SignProPlus-Alex

- Post #8

- Forum: General Signmaking Topics

-

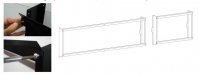

Looking for odd sign hanging bracket system.

I made a few signs for Walmart but never seen hardware now it all make sense to me.- SignProPlus-Alex

- Post #7

- Forum: Product and Supplier Referrals

-

HDU Plaque Fail When Inset in Stone

Only low density duna are expanded polyunsaturate. all high density foams are HDU- SignProPlus-Alex

- Post #20

- Forum: Dimensional Signs

-

How would you make 600 of these?

Most likely those are made by using hot stamp.- SignProPlus-Alex

- Post #6

- Forum: General Signmaking Topics

-

Xerox 8265 printer

We retire our 8265 about 6 month ago. I was using bulk ink system with external chip readers and just pull chips after start up. As far as I know you have to replace whole motherboard to get around it. I can sell you ink system and some ink. Pm me if you are interested.- SignProPlus-Alex

- Post #2

- Forum: Mutoh