-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Wrapping a car for $120 bucks

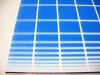

Hard to say, it almost looks like Oracal 970 wrap film but he looks of it, I think I can almost see the Oracal grid on the backing paper in one of the photos. Laying it wet ain't the smartest... And those wheels are sexy, almost bought them for my Mini.- Letterbox Mike

- Post #4

- Forum: General Signmaking Topics

-

-

4over business cards

it sounds like you didn't convert your fonts to outlines, but that shouldn't matter with the .jpg. I wouldn't upload a .jpg anyway, try a .tiff, cmyk, 600dpi.- Letterbox Mike

- Post #6

- Forum: General Signmaking Topics

-

rgb...cmyk....so cornfused!...ugg

Yeah Bob, I'm not sure what you're doing but I just tried what you're talking about with about 20 vastly different files, all CMYK, and observed absolutely no color change whatsoever in any of them.- Letterbox Mike

- Post #21

- Forum: Flexi

-

Double Sided Banners Stiacking to Roll?

Good to know. Now go find a new technician! Out of curiosity, why did he tell you to turn the heat off?- Letterbox Mike

- Post #29

- Forum: General Signmaking Topics

-

Double Sided Banners Stiacking to Roll?

We run ours at 48/45/50. You may need to raise the head to high (we don't have to), but environmental conditions can affect how the media takes heat too. That stuff can handle a ton of heat. Not sure what profile you're printing with but we've found the Avery MPI3100 glossy calendered 540x1080...- Letterbox Mike

- Post #25

- Forum: General Signmaking Topics

-

Double Sided Banners Stiacking to Roll?

I'd find a new tech... Cheap banner material will have issues with excessive heat, it'll buckle. That doesn't mean you shouldn't run heat, it means you should experiment with heat settings until you find heat that the media lays flat, if you can't get it to lay flat, find different material. In...- Letterbox Mike

- Post #21

- Forum: General Signmaking Topics

-

rgb...cmyk....so cornfused!...ugg

I know there's a big debate about this and most people say RGB, but we rasterize all .pdfs in photoshop at 150dpi CMYK and they print great. We're using Onyx, but for us it nails PMS colors every time, we've never had a color issue. I've tried doing this as RGB and while the colors look nice and...- Letterbox Mike

- Post #2

- Forum: Flexi

-

Double Sided Banners Stiacking to Roll?

No they won't. Trust me, you need to turn your heaters on. Heat is a critical element to solvent printing, without it it does not work right. Solvent inks require heat to form a bond with the media. The only way you can get away with running less heat is if you're running a true full solvent...- Letterbox Mike

- Post #17

- Forum: General Signmaking Topics

-

Double Sided Banners Stiacking to Roll?

Your heaters are off, that's why you're having the problem. Solvent ink has to have ink to work right, otherwise it's just sitting on top of the media and not soaking in. I'm not surprised in the slightest that you're having the problem if you're not using any heat. You didn't mention what...- Letterbox Mike

- Post #15

- Forum: General Signmaking Topics

-

JV3-160S Question - How to calibrate

Do you mean a bidirectional calibration or media comp calibration or an actual head alignment?- Letterbox Mike

- Post #3

- Forum: Mimaki

-

very large write on erase magnetic board prob

We've done lots of magnetic menu boards using 24 ga roofing sheet metal. Most cities will have a roofing supply house that stocks it in alot of colors, including white and black. It's still steel so it's not exactly light, but you could attach it somehow to a wood backer and it would be great...- Letterbox Mike

- Post #3

- Forum: General Signmaking Topics

-

JV3 160 Print Issues

Just had a very similar problem, different ink brand though. Clean the inside of the "doghouse" really well. We were getting alot of gummy ink buildup way back in there (farther back in it than you can really see or easily reach when doing normal cleanings). The wiper was dragging that gummy...- Letterbox Mike

- Post #18

- Forum: Mimaki

-

Tailgate wrap

We're usually at about $250-300 for a fullsize truck tailgate wrap, plus design. If it's a tough tailgate like a Chevy Avalanche or something with embossed letters we'll add a bit more, those can be a bit more time consuming to wrap. If it's a small tailgatelike an S10 or Ranger we may be closer...- Letterbox Mike

- Post #2

- Forum: Sales, Marketing, Pricing Etc.

-

Disposal of Mimaki waste ink

Get a "big mouth" plastic tub of kitty litter. Pour the waste ink in. Set outside in the sun for a few days to allow it to dry up. Put the lid on and throw it away. Dunno if that's technically legal, but our dealer told us to do it that way and according to them as long as the ink has dried it's...- Letterbox Mike

- Post #2

- Forum: Mimaki

-

Aaaaaaaaaaargh PopUP material

You don't have to laminate them, just like you don't have to laminate anything, but it improves durability. Retractable banners are subjected to alot of abuse, between transporting them and setting them up and tearing them down the chances for scratching or scuffing the graphic are siginficant...- Letterbox Mike

- Post #13

- Forum: General Signmaking Topics

-

Aaaaaaaaaaargh PopUP material

Every one of these has failed after being rolled in in the retractable base for no more than 2-3 days max.- Letterbox Mike

- Post #12

- Forum: General Signmaking Topics

-

Aaaaaaaaaaargh PopUP material

I agree with what you're saying... The thing is, the PopUP actually prints better than the PosPRO. It's a better looking product and customers are thrilled with it (aside from the obvious laminate flaking off thing). I have no problem using it if it's just a matter of finding the right laminate...- Letterbox Mike

- Post #6

- Forum: General Signmaking Topics

-

Aaaaaaaaaaargh PopUP material

Yup, nothing gets laminated within24 hours, most of these were laminated 48+ hours after printing. And we run an infrared dryer on full blast on our printers to help speed drying. Outgassing was not the issue here. I wish it was, at least it would be easy to diagnose then...- Letterbox Mike

- Post #3

- Forum: General Signmaking Topics

-

Aaaaaaaaaaargh PopUP material

This stuff will be the end of me. I posted this once a while back but got no response whatsoever, so I'll try this again. What do you people laminate Fellers PopUP material with for retractable banner stands? We've always used Sihl PosPRO 200 with lamex 3mil luster embossed polycarb...- Letterbox Mike

- Thread

- Replies: 19

- Forum: General Signmaking Topics

-

Thinking about a storefront. Any thoughts, suggestions?

I'd pass, the space sounds like the negatives outweigh the positives. If you're limited on what you can produce there and limited by a one way street, and physically limited by a very small space, I'd guess you're regret it in short order. If the space works out well and your business grows...- Letterbox Mike

- Post #9

- Forum: General Signmaking Topics