-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Question Public Hearing sign specs that don't compute

I've come across several Public Hearing sign spec sheets provide by clients that never really compute. Anyone else?- myront

- Thread

- Replies: 22

- Forum: Designs & Layouts

-

-

Question Warping Substrate - HP Latex 365

Our print tech has taken an empty media tube and routed out about a 1/4" slit down the length of it. Once the leading edge is out far enough he takes one of those clamping type pop up banner attachments and clamps to the leading edge of the media, then he slips that tube over it all.This will...- myront

- Post #16

- Forum: Hewlett Packard

-

Finecut Connection issue

We use a CG-160 FX II with win10, Corel X7 and FineCut 8. No problems. -

-

Moving objects in Coreldraw while holding CTRL?

click and hold on the group first then hold control to move -

-

Does anyone else hate online reviews?

Customer writes we "put the wrong phone number" on his magnet. We emailed a proof and he replied with an approval. Why is it our fault? I don't put a lot into online reviews but I do check. We get people in all the time that what a color change wrap and get all upset about the price quote. "It...- myront

- Post #19

- Forum: General Chit-Chat

-

Suggestions File size

#1 mistake - designing in photoshop. A vector program with raster elements from photoshop is acceptable. #2 - designing at full scale 300 dpi. Using a vector program design at scale but any raster images not to exceed 150dpi.- myront

- Post #9

- Forum: Designs & Layouts

-

-

banners

Indy Imaging but be mindfull if the banners have to be finished to an exact measurement. There sizes can vary by as much as a couple of inches.- myront

- Post #3

- Forum: General Chit-Chat

-

RIP Computer

Can't give much advice on specific pc configuration for a RIP station but it doesn't have to be as robust as a design workstation. I find that more and more what slows print jobs from ripping is on the designers. All vector files should be ripped as pdf and the settings can be set up to make...- myront

- Post #2

- Forum: General Software

-

CJV150-130 Issues with Reg Mark/Leaf Cutting

The camera is located alongside the cutting blade. You can watch it drop down to read the first mark. What type of reg marks are you using? Using sheet leaf or roll? We use roll no matter what it is. -

CJV150-130 Issues with Reg Mark/Leaf Cutting

We've found bits of vinyl stuck to the "camera" on occasion. Wrap a lint free cloth around a ruler and spray with alcohol then rub the camera. Also ensure either all the pinch rollers are set to high pinch or at least the two outermost ones are set to max and the inner ones lower. Anything over... -

artwork

Keep in mind that the artist may not have any experience with creating "cut ready" art. For years I created artwork for print only. I had no idea how the plotting process worked. p.s. I do now. Now if we can get these "wanna be" designers to quit dropping a jpg into photoshop and saving as as...- myront

- Post #7

- Forum: General Chit-Chat

-

Ugh....WHY!?!?!

We order 4' x 8' sheets of alum all the time and they have the blue or pink cover on them. We peel that off right away. Couldn't they just peel that off before chopping them up. Takes all of 5 seconds. But to peel them off after chopped is nuts.- myront

- Post #37

- Forum: General Chit-Chat

-

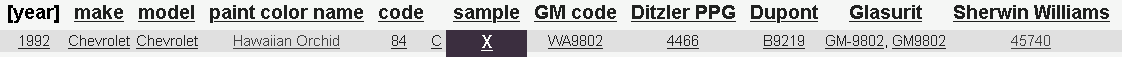

Need Help Need a Cross-Reference Color Code

Hopefully you have access to the actual vehicle. Throw the pantone book at it and pick the closest pantone. Print small (3") swatches with varying color and laminate. Now hold those up to the vehicle and pick the best or have the customer pick.- myront

- Post #2

- Forum: General Signmaking Topics

-

-

Circle sticker issues

Our cuts are always a bit off like that. Depends on the both the size of the circle and size of the outline/stroke. Helps to keep to a short runs. Be sure to use all pinch rollers too.- myront

- Post #9

- Forum: Labels and Decals

-

Cool things

Got us beat. Did some graphics on cessna's before but the don't go up that far. lol- myront

- Post #7

- Forum: General Chit-Chat