-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New HP Latex 700 and 800 series - with White ink

- Thread starter balstestrat

- Start date

Zendavor Signs

Mmmmm....signs

The 300 series made some significant improvements with both color consistency and length. It is not perfect, but much better. I would hope with the lessened heat of the 700/800 series (plus being a couple strides ahead of the 300 series printers) that these should improve even more.does the W800 have a better color consistency from panel to panel? Also, does it keep the right size? On my L260, with a 9ft long print, I could loss up to an inch. It's been a real problem for murals and align pannels.

bigben

Not a newbie

The 300 series made some significant improvements with both color consistency and length. It is not perfect, but much better. I would hope with the lessened heat of the 700/800 series (plus being a couple strides ahead of the 300 series printers) that these should improve even more.

Exactly what I hope. But my only comparaison is my L260.

balstestrat

Problem Solver

does the W800 have a better color consistency from panel to panel? Also, does it keep the right size? On my L260, with a 9ft long print, I could loss up to an inch. It's been a real problem for murals and align pannels.

By all means it should be better (not saying 0.00% perfect) now. L500 was already a little better with length than L300 was.The 300 series made some significant improvements with both color consistency and length. It is not perfect, but much better. I would hope with the lessened heat of the 700/800 series (plus being a couple strides ahead of the 300 series printers) that these should improve even more.

HP says length accuracy should now be up to +/-0.5 mm/m. It used to be 1-2mm. Colour consistency should be better as well but I think we all know that when you start having those old and used printheads and you never did the colour calibration, you will eventually start seeing the issues. But that's also to be expected and not really a "defect".

All this will be something to be seen. Takes time to gather more user experiences.

I've printed some tiles and all came out perfect for me, did some wallpaper, banner, vinyl. The lower temperature really helps and the new way the take-up works as well.

Mike Perth

New Member

Hi Team

Our 800w was installed yesterday and we've run a couple of medium sized wallpaper jobs as a test. We have been holding off for this machine and have managed to nurse our 260 until now. A Colorado would have been a good option too but we really need to be able to print white and so we waited. We only print wallpaper and after these tests we’re sure we've made the right decision and see this machine as a driver for new products and customers. We’re running our usual stocks through at 6 pass, the quality is perfect and it’s fast! We won’t be using white for a week or two as we have a heap of work to catch up on before we have time for a play. The first bigger wallpaper was printed with the calibrated take up reel and was perfect in length and colour, the second we ran without using the “correct” take up method and the panel lengths were different from each other by 5-7mm (the colour match was perfect), we won’t be doing that again!

Mike

Our 800w was installed yesterday and we've run a couple of medium sized wallpaper jobs as a test. We have been holding off for this machine and have managed to nurse our 260 until now. A Colorado would have been a good option too but we really need to be able to print white and so we waited. We only print wallpaper and after these tests we’re sure we've made the right decision and see this machine as a driver for new products and customers. We’re running our usual stocks through at 6 pass, the quality is perfect and it’s fast! We won’t be using white for a week or two as we have a heap of work to catch up on before we have time for a play. The first bigger wallpaper was printed with the calibrated take up reel and was perfect in length and colour, the second we ran without using the “correct” take up method and the panel lengths were different from each other by 5-7mm (the colour match was perfect), we won’t be doing that again!

Mike

bigben

Not a newbie

Hi Team

Our 800w was installed yesterday and we've run a couple of medium sized wallpaper jobs as a test. We have been holding off for this machine and have managed to nurse our 260 until now. A Colorado would have been a good option too but we really need to be able to print white and so we waited. We only print wallpaper and after these tests we’re sure we've made the right decision and see this machine as a driver for new products and customers. We’re running our usual stocks through at 6 pass, the quality is perfect and it’s fast! We won’t be using white for a week or two as we have a heap of work to catch up on before we have time for a play. The first bigger wallpaper was printed with the calibrated take up reel and was perfect in length and colour, the second we ran without using the “correct” take up method and the panel lengths were different from each other by 5-7mm (the colour match was perfect), we won’t be doing that again!

Mike

Good to know. Does loading the take-up waste alot of material? And by ''calibrated take up'', what do you mean?

balstestrat

Problem Solver

If you want to start with attaching to take-up you will waste about 1000mm. Calibrating that it just does few movements to correct the advance with the take-up pulling the material.Good to know. Does loading the take-up waste alot of material? And by ''calibrated take up'', what do you mean?

jimmmi

New Member

If you want to start with attaching to take-up you will waste about 1000mm. Calibrating that it just does few movements to correct the advance with the take-up pulling the material.

Like 300 and 500 calibrating OMAS when the media is on take up from the beginning? Same thing?

balstestrat

Problem Solver

Yeah same thing.Like 300 and 500 calibrating OMAS when the media is on take up from the beginning? Same thing?

Megan Burkhardt

New Member

So by them moving to a separate overcoat ink which they recommend not be used if you laminate, are they admitting to lam issues for the prior gen ink?

What Kind of lamination issues have you had? Im working off a dinosaur at the moment (L26100) yeah its bad. but weve always had issues with cold lamination being almost cloudy - i wouldnt doubt its the terrible quality of the lamination- but i wonder if it could be the ink as well?

XtremeXccessories

New Member

What Kind of lamination issues have you had? Im working off a dinosaur at the moment (L26100) yeah its bad. but weve always had issues with cold lamination being almost cloudy - i wouldnt doubt its the terrible quality of the lamination- but i wonder if it could be the ink as well?

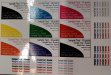

I believe he's talking about the 300 (and I believe 500) series having issues with the laminate sticking to the printed areas; the darker the print the easier it just peels off.

Customer supplied pixilation, BTW.

Attachments

robibilic

New Member

No one but you are comparing to the old tech of solvent. If you didn't understand my answer, maybe try to understand the question first. They asked how HP improved the gamut significantly over the previous generation of Latex... No one in here cares about epson solvent.

It is not solvent. It is the first Epson "latex" printer.

Christian @ 2CT Media

Active Member

Umm he was referring to the 80600 which is their solvent. Their alternative ink is a resin not latex, similar functionality but different approach.It is not solvent. It is the first Epson "latex" printer.

In his post to me he mentioned the R, but their gamut is very similar but the epson holds advantage in gradients and color transition due to smaller droplet

balstestrat

Problem Solver

Charlie J

New Member

Questions I have:

- How are the reds? Any improvement from the 300 series?

- I'm a flexi user, I'm assuming I would be forced to use Onyx with the new machines?

- Let's say I buy a white ink model, and I go a month without printing white. Are the printheads going to be okay as long as they are removed?

balstestrat

Problem Solver

-Reds better than on L300. How much? I don't know how to compare, it's better. Ask for some samples.Questions I have:

- How are the reds? Any improvement from the 300 series?

- I'm a flexi user, I'm assuming I would be forced to use Onyx with the new machines?

- Let's say I buy a white ink model, and I go a month without printing white. Are the printheads going to be okay as long as they are removed?

-You can upgrade and use Flexi if you want to, L700/800 is supported.

-It will be fine for a month.

Mike Perth

New Member

Have you been having issues with the take up? We initially were going OK but we now have panel length issues with all wallpapers.If you want to start with attaching to take-up you will waste about 1000mm. Calibrating that it just does few movements to correct the advance with the take-up pulling the material.

balstestrat

Problem Solver

I have not. I know there's few bugs with the take-up but those shouldn't affect the length.Have you been having issues with the take up? We initially were going OK but we now have panel length issues with all wallpapers.

Have you tried the profile that keeps constant tension and doesn't do the pull-release? I don't remember if that's how it's on wallpaper already or not.

Mike Perth

New Member

We’ve stopped using the take-up on auto after the calibration and are now running the prints to the floor and winding on by hand which seems to solve our length issue, I’ll look at the profile and run through your suggestion tomorrow. Just out of interest does your curing module sit square on the printer frame, ours drops 1cm from left to right.I have not. I know there's few bugs with the take-up but those shouldn't affect the length.

Have you tried the profile that keeps constant tension and doesn't do the pull-release? I don't remember if that's how it's on wallpaper already or not.

balstestrat

Problem Solver

It's not flush from the top? Yeah mine sits straight. I would inspect closer if yours seems crooked. Could be something wedged in between blocking the lower position etc.We’ve stopped using the take-up on auto after the calibration and are now running the prints to the floor and winding on by hand which seems to solve our length issue, I’ll look at the profile and run through your suggestion tomorrow. Just out of interest does your curing module sit square on the printer frame, ours drops 1cm from left to right.

Last edited: