-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

I'm looking for good vehicle decal software.

LOL...still isn't what he asked for....he said he doesn't print. That's about all Aurora has.- eahicks

- Post #8

- Forum: Vehicle Graphics

-

-

Need Help New printer is not printing the same colors as old

No 2 printers print the same. You will probably need to build your profile for canvas, for that printer. -

Need help printing TEST PATTERN FILL in service mode.

Would not be a profile issue if it is the printer's test print. -

Question Is There a Clear Vinyl for Textile Use?

Why do you say it has to be applied wet? Which brand are you referring to? I use a couple different clears and lay them dry nearly every time. Of course it's usually with a laminator. -

Completely New to Signs

There's a lot of videos on Youtube, everything from explanation of substrates to application of vinyl, and everything in between. Spend a few days searching and watching those.- eahicks

- Post #24

- Forum: New Member Introductions

-

What is a Vinyl Sticker and what is a Vinyl decal?

Sticker? I barely know 'er.- eahicks

- Post #49

- Forum: General Signmaking Topics

-

Avery Vinyl with 3M Overlam...no-no or?

You can mix brands all you want, I have found, with no issues. I would just be sure to use CAST lam with CAST vinyl and CAL lam with CAL vinyl. They will shrink at different rates.- eahicks

- Post #20

- Forum: Vehicle Wraps

-

Need Help Folding Portable Trade Show Booth Prints Questions...

We also print on vinyl, mount to HIPS, and laminate with thin polycarb laminate. I will probably begin printing on the non-curl supersmooth retractable banner material and laminate that with a thicker polycarbonate in the future. Eliminates a production step. We don't do these that often though.- eahicks

- Post #6

- Forum: General Signmaking Topics

-

Laminate & substrate for dimensional lettering/logos

We buy our laminate sheets straight from Wilsonart Sent from my iPhone using Tapatalk- eahicks

- Post #4

- Forum: Laser Cutters

-

Application tape Help!

But with a LINER?? Never seen that.- eahicks

- Post #7

- Forum: Product and Supplier Referrals

-

This one has me stumped

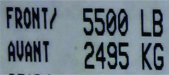

VCR OSD MONO is close... http://www.dafont.com/vcr-osd-mono.font?text=AVANT+5500 Search some of the others there...- eahicks

- Post #2

- Forum: Fonts and Typography

-

Is it OK to apply ControlTac with a wet application?

He said Controltac, so that is 3M.- eahicks

- Post #4

- Forum: General Signmaking Topics

-

Is it OK to apply ControlTac with a wet application?

I can't imagine why you would need Rapid Tac. If you tape hinge it you can lay half and half with no issues. Almost impossible to leave any bubbles.- eahicks

- Post #2

- Forum: General Signmaking Topics

-

Suggestions Brick Wall Vinyl?

If the cost of a substrate scares you and you don't sell the job for enough money to cover that cost, something is not right. That picture looks like simple solid color cut vinyl to me. Just cut any old cast vinyl, use a heat gun/torch and felt squeegee.- eahicks

- Post #5

- Forum: Product and Supplier Referrals

-

-

So what's with the new.......................................

Well my text entry issues went away with whatever change was made. Iwashavingissueswithnospacebarforawhile.- eahicks

- Post #5

- Forum: General Chit-Chat

-

-

custom imprint carpet mat

That's right - we don't make them. So no we wouldn't show up in that search. But if I needed to buy one, I'd search Google.- eahicks

- Post #5

- Forum: Product and Supplier Referrals

-

custom imprint carpet mat

What's freaking hilarious is when you search for custom printed rugs.....FASTSIGNS pops up as a link!!- eahicks

- Post #3

- Forum: Product and Supplier Referrals

-

custom imprint carpet mat

http://lmgtfy.com/?q=custom+printed+rugs- eahicks

- Post #2

- Forum: Product and Supplier Referrals