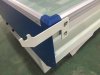

My Fayon Laminator just turned up 3 weeks ago, I could write an entire essay on the disappointment with my flatbed Laminator.

The table frame is uneven, when the roller runs over it creases the vinyl and creates bubbles throughout the whole length of the laminator. The steel is rusty when the paint has been scratched. Looks like the frame has been left in the weather for long time.

The roller has already fallen off the machine and broken the heater core (Second Day), Cables too short and jammed between the steel casing and LED’s flicker randomly

I was told they have seen the manufacturing issue before and their only recommendation is pack steel between the supports to support the glass ;\ to level it,

With the glass weighing 300kg so not looking forward to lifting up and down without breaking it. With 13 supports have gaps ranging from 1 to 4mm so its going to be a roulette game to find which one needs supporting and which ones doesnt.

I offered to pay for one of their experienced engineers with the correct tools to fly over but they advise they are too busy to fix the issue and won’t provide any assistance or compensation.

I would highly recommend to stay away from this machine and pay for a named brand who supports there products locally or spend the time building your own.

Also it only sits at 80cm high so very painful working height unless your 5ft tall

I would highly recommend to stay away from this table (I can’t even call it a laminator), what a waste of $10,000k.

After doing some further research i found 3 people who bought these locally and they also similar manufacturing issues