xkellyx

New Member

We purchased our HP Latex 310 in November of 2015. Almost immediately we had issues with image quality (which we posted about on here). With help of HP Tier 3 support, we were able to get the machine printing well enough.

At that time the engineer we were working with created a profile for us to use. On a recent call with level 2 support they were shocked to find out we were printing with an 18 pass profile and even more shocked when we told them and then PROVED that a level 3 HP engineer had created the profile for us.

The machine has been covered by the original warranty and then a maintenance contract.

We are not a high volume shop. Over the past few years, we have had to have support on-site to replace numerous parts which have failed. We print mostly inexpensive promotional decals/stickers. The trailing cable and tubes on the machine have been replaced three times.

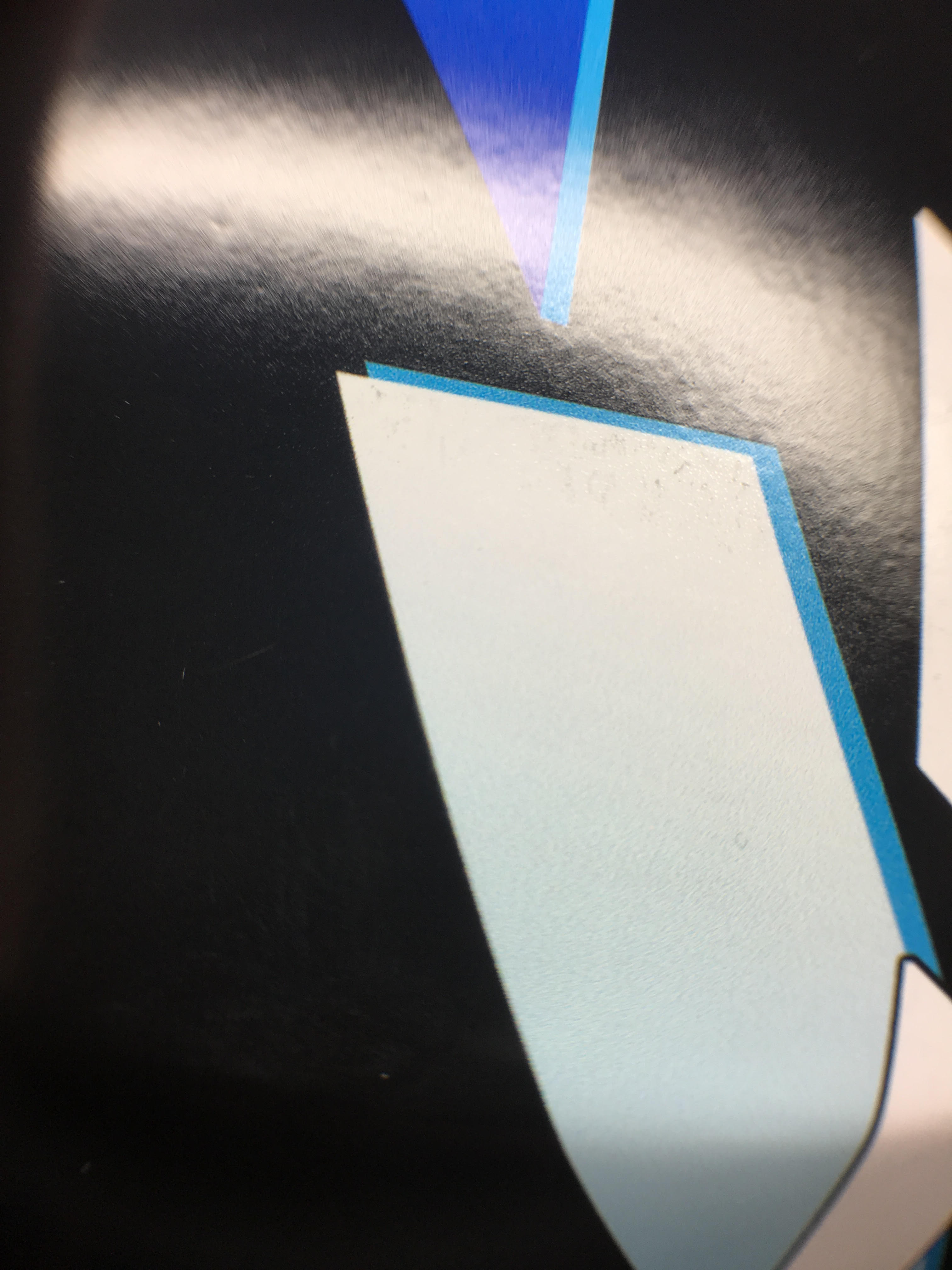

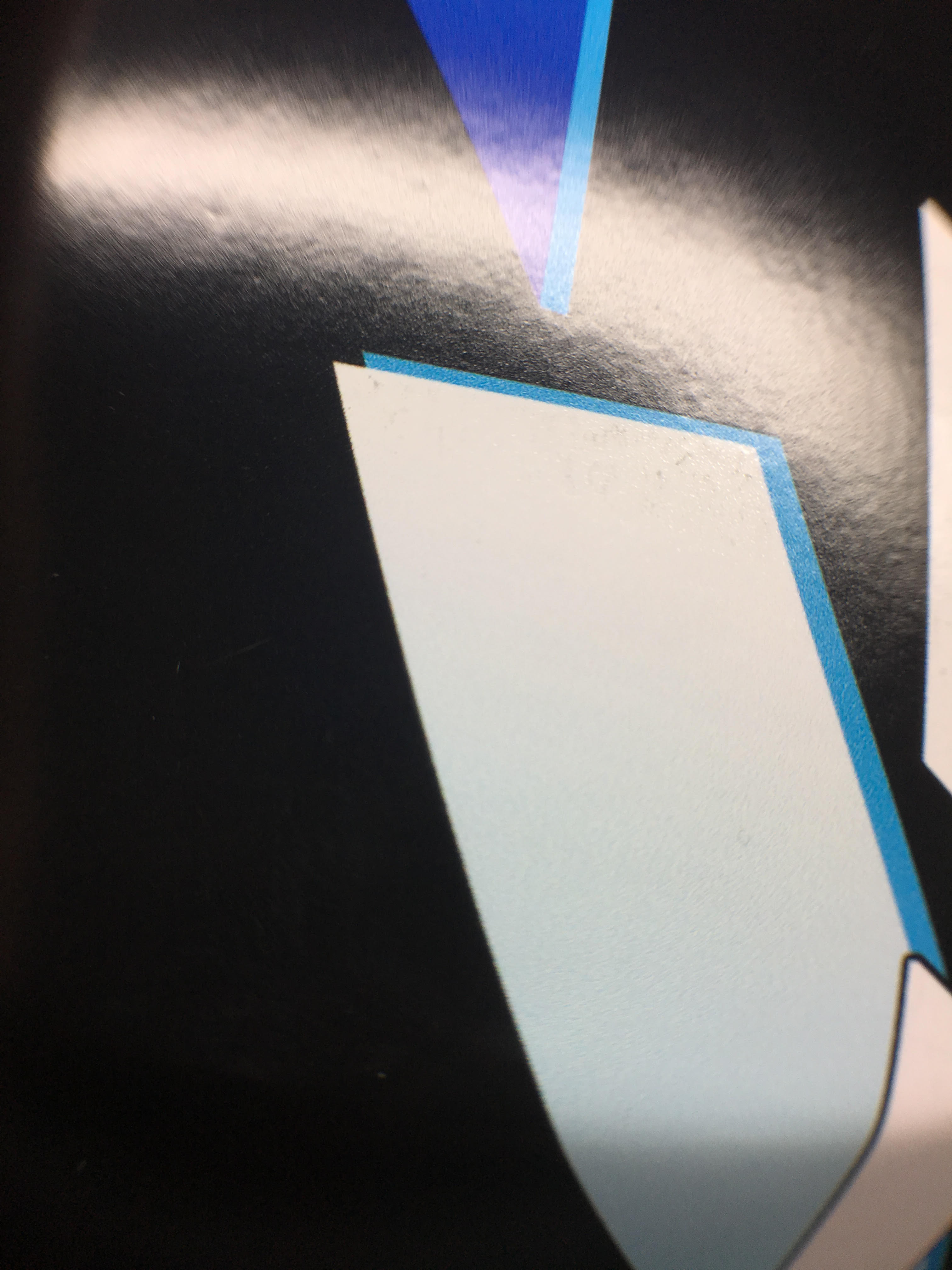

We are currently dead in the water. When printing dark saturated colors, it creates what appears to be some form of overspray. For instance, if you have a heavy black print with a white knockout, there will be black ink artifacts in the white area. The second issue is that the ink is not curing properly. Especially with dark saturated colors.

Our HP tech has been on site for three weeks now. He has basically replaced everything from the pinch rollers to the heating system and fans. We have tried three different sets of print heads, replaced the carriage, the trailing cable, and tubes (which incidentally were leaking AGAIN just not bad enough for us to notice yet) as well as numerous other parts I can't remember.

The issue occurs regardless of the media or profiles used. HP has sent out media and profiles for us to test on. Curiously, the ink not curing issue is particularly bad on the Print all Plots which is printed from the printer interface and is independent of the RIP. The overspray/haze issue is also visible on all the tests printed directly from the printer (again without the RIP).

Another really interesting fact is that we printed a test print and shipped it to the Engineers at HP. The print was dry and did not smear when we touched it after it was printed. It was also "dry" when it was put in the tube at FedEx by our Tech. Yet, when it reached the HP Engineer it had "re-wet" (his words not mine).

The machine is housed in a climate controlled environment in the North East. Humidity and static have been excluded as an issue. One engineer theorized the overspray/haze could be from aerosols not burning off properly and suggested running the machine at a higher temperature. Which makes little sense since the entire machine was in pieces yesterday, which I would assume would let the aerosols dissipate.

Furthermore, the overspray/haze has a recurring pattern at times, which could indicate that it is not random particulate landing on the media and curing. It also only occurs in the areas in which ink is printed and not outside of those areas even though those areas are exposed to both the inside of the machine as well as the heating units. If aerosols were the culprit one could expect artifacts to land in any whitespace, not just the white space in the area printed.

My tech is out of parts to replace and said that he thinks they will be sending an engineer to our site. Has anyone who is printing on a Latex experienced anything like this?

My current thought is that the printer had a fundamental issue from the start which the profile provided by HP covered up and now it is no longer working.

To say that I am frustrated is an understatement.

See photos below.

At that time the engineer we were working with created a profile for us to use. On a recent call with level 2 support they were shocked to find out we were printing with an 18 pass profile and even more shocked when we told them and then PROVED that a level 3 HP engineer had created the profile for us.

The machine has been covered by the original warranty and then a maintenance contract.

We are not a high volume shop. Over the past few years, we have had to have support on-site to replace numerous parts which have failed. We print mostly inexpensive promotional decals/stickers. The trailing cable and tubes on the machine have been replaced three times.

We are currently dead in the water. When printing dark saturated colors, it creates what appears to be some form of overspray. For instance, if you have a heavy black print with a white knockout, there will be black ink artifacts in the white area. The second issue is that the ink is not curing properly. Especially with dark saturated colors.

Our HP tech has been on site for three weeks now. He has basically replaced everything from the pinch rollers to the heating system and fans. We have tried three different sets of print heads, replaced the carriage, the trailing cable, and tubes (which incidentally were leaking AGAIN just not bad enough for us to notice yet) as well as numerous other parts I can't remember.

The issue occurs regardless of the media or profiles used. HP has sent out media and profiles for us to test on. Curiously, the ink not curing issue is particularly bad on the Print all Plots which is printed from the printer interface and is independent of the RIP. The overspray/haze issue is also visible on all the tests printed directly from the printer (again without the RIP).

Another really interesting fact is that we printed a test print and shipped it to the Engineers at HP. The print was dry and did not smear when we touched it after it was printed. It was also "dry" when it was put in the tube at FedEx by our Tech. Yet, when it reached the HP Engineer it had "re-wet" (his words not mine).

The machine is housed in a climate controlled environment in the North East. Humidity and static have been excluded as an issue. One engineer theorized the overspray/haze could be from aerosols not burning off properly and suggested running the machine at a higher temperature. Which makes little sense since the entire machine was in pieces yesterday, which I would assume would let the aerosols dissipate.

Furthermore, the overspray/haze has a recurring pattern at times, which could indicate that it is not random particulate landing on the media and curing. It also only occurs in the areas in which ink is printed and not outside of those areas even though those areas are exposed to both the inside of the machine as well as the heating units. If aerosols were the culprit one could expect artifacts to land in any whitespace, not just the white space in the area printed.

My tech is out of parts to replace and said that he thinks they will be sending an engineer to our site. Has anyone who is printing on a Latex experienced anything like this?

My current thought is that the printer had a fundamental issue from the start which the profile provided by HP covered up and now it is no longer working.

To say that I am frustrated is an understatement.

See photos below.