-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

JV3 RIP Software

I tihnk he means can it tile the jobs?- jfiscus

- Post #6

- Forum: Product and Supplier Referrals

-

-

Boat wraps

I sure wouldn't. Heck, I'd never use 210 for anything after the horror stories I've seen from it. Boats need proper cast vinyls & lams and edge sealer.- jfiscus

- Post #3

- Forum: Vehicle Wraps

-

Discussion How to layer a 7 foot sign.

We print them, that is the secret. For registration when using translucents you can lay knifeless tape down first where the lap is going to be and then install both panels and pull the tape and end up with a perfect butt-seam.- jfiscus

- Post #5

- Forum: Installation Equipment & Techniques

-

Vinyl not sticking to weather strip

Remove the vinyl and stick it to some scrap backing paper for now. Get some 3M Primer 94 and brush it on there, let it dry. Now, reinstall your graphic carefully and post-heat it for extra grip. Use some 3M edge sealer also if the edges still aren't happy. Or, get a (sample) roll of Arlon...- jfiscus

- Post #19

- Forum: General Signmaking Topics

-

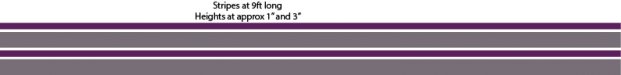

Suggestions Cutting Stripes Straight

I'd bet that the vinyl you're using actually does come in a sprocket-fed variety. We are primarily a 3M shop also and run quite a lot in sprocket fed variety, sometimes you have to buy it pre-converted to sprocket-fed as a "Gerber" vinyl, but the 180mc versions are also available in sprocket-fed...- jfiscus

- Post #19

- Forum: Tips & Tricks

-

How to vectorize a vehicle to look like clipart?

Yes, I work primarily in Adobe CC products.- jfiscus

- Post #30

- Forum: Designs & Layouts

-

JV3 RIP Software

I have a friend who has a JV3 and absolutely hates his RIP (Rasterlink) and wants to upgrade to a different RIP without breaking the bank. Does anyone know a solution for him? I know Onyx (expensive) will do it, but is there anything else out there that will or a subscription-based software that...- jfiscus

- Thread

- Replies: 8

- Forum: Product and Supplier Referrals

-

looking for a material

Grimco is our supplier for Gerber now that Advantage is gone. Gerber has a nice new catalog out also. -

Suggestions Cutting Stripes Straight

Very simple job to do. A Gerber Edge & Gerber sprocket fed plotter would make short/easy work of this project. Then you would have the colors already pre-spaced and you'd just have to weed and mask it for a simple easy install. A roll slitter could make the individual stripes easily enough...- jfiscus

- Post #15

- Forum: Tips & Tricks

-

How to vectorize a vehicle to look like clipart?

I drew this up in vector format from a customer's drawing of their car. There is no substitute for putting vector points together; no filter is going to get you to quality vectors. I think this took 10-12 hrs of intense drawing and had 22 layers to keep things organized/locked while I was...- jfiscus

- Post #28

- Forum: Designs & Layouts

-

Question Pull-Up Banner Issue

Those roll up onto a "core" inside the base, so there is no reason for them to have wrinkles except for mis-handling.- jfiscus

- Post #6

- Forum: General Signmaking Topics

-

Hanging a banner from a car for a parade?

Tape, just make the banner without hems or grommets and have them tape it to their car. That photo is of a fabric "banner" not a vinyl banner.- jfiscus

- Post #3

- Forum: General Signmaking Topics

-

illustrator gradient question

Sounds like a horrible background color (gradient) for a wrap. Just sayin. -

Discussion Railroad Car Decals

Get a good software program and processes in your shop to track orders. Treat every order individually.- jfiscus

- Post #3

- Forum: General Signmaking Topics

-

How is business so far this year?

Business is up around 150% from this time last year, which was up 100% from the year before that.... I know we're sending out more jobs than ever, but also costs are rising all over and mistakes are up 500% from a couple years ago. Hard to find good help that wants to show up to work. Installers...- jfiscus

- Post #17

- Forum: Business Management

-

RapidTac RAPID REMOVER

It works well, but we usually just use the 3M remover in the metal can, it's what ours guys seem to prefer. I think we buy it at the local autobody/paint store.- jfiscus

- Post #8

- Forum: Vehicle Wraps

-

Issues with 3m 180mc

We haven't printed either of those two vinyls here, but I'm wondering if there is a surface coating to optimize latex printing on the one that is giving you issues? It looks like a latex/solvent issue to me from when we had latex and solvent machines in-house and accidentally put the wrong roll...- jfiscus

- Post #43

- Forum: General Signmaking Topics

-

Need Help What a FAIL. Glass door all scretched up. Anything to fix it?

The black/stronger razor blades can definitely scratch glass. Stainless ones do not.- jfiscus

- Post #12

- Forum: General Signmaking Topics

-

Buyer Beware! Avery Supreme Wrap Material.

Also, always install your panels FLIPPED like a regular wrap would be printed when installing solid color wrap vinyl. Due to the process of making the wrap vinyl, color can vary slightly from the left to right edge of the roll. I believe 3M now has some arrows on the liner, but most do not know...- jfiscus

- Post #6

- Forum: Vehicle Wraps

-

3M MCS Certified Printer Suggestions

To the poster above with banding isues, the material feed calibration setting looks to be your issue.- jfiscus

- Post #29

- Forum: Product and Supplier Referrals