-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

3D Print of this anyone (UK) based

ewded that's a good idea well worthy of consideration .. i am in the uk and 3d print for a hobby but my 3d drawing cad skills will let me down here- woolly

- Post #5

- Forum: 3D Modeling

-

-

How to fine tune head carriage height on an XC-540

haven't seen it mentioned but does the wiper assembly move up and down with the head height so the wipers wipe correctly for each height and got stuck on a higher level- woolly

- Post #11

- Forum: Newbie Forum

-

Roland XC540 Cutting Pressure Problem

possible from past experience the main ribbon cables failing and or muck or bit of vinyl in the actuator which is the cup shape bit next to the blade holder in side are fine winding's so a lot of care required . check for free up down movement of the actuator with the machine switched off. just...- woolly

- Post #3

- Forum: Digital Printing

-

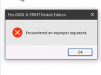

FlexiSign: "Encountered an improper argument."

i would have asked it if it wanted a 5 min or 10 min argument ... ... sorry back to thread.. -

Roland VS-300i Contour Cuts off after 30 inches

lower the cut and up speed, sharp knife, add more rollers if you can. also thicker materials do not like bending over the bed like cast types which comes back to you adding a surface each side for the material to slide on to and as you say reduces the weight problem i did this with a graphtec... -

Roland Versacamm sp540i - Not printing teal.

print the spot colour sheets using the profile and quality you need from versaworks then chose the spot colour then dial in the number very useful when chasing colours -

Question Service mode for head alignment

by the looks of your test print you will need to adjust the position manually of the m+y head before any of the electronic adjustments info should be in those pdfs. well worth the time and effort to get right. -

Suggestions Anyone here wrapped a bike...as in bicycle?

haven't fully wrapped one but done fair amount of protection stuff i don't think i would even try got to be easier to paint it then add some colour or printed bits, easy to make and digitize templates for down tubes and fork ends, bit of dayglow a few sponsor logos will soon brighten it up have...- woolly

- Post #2

- Forum: Vehicle Wraps

-

Pontoon Boats

from the uk so had to look up pontoon boat, i can see the attraction of stability and use in shallow water but they are ugly- woolly

- Post #9

- Forum: General Chit-Chat

-

Printing white and metallic ink mama cjv150-75

i run a vs540 wt mt and yes its slow compared to normal prints approx half speed.. fastest for that type of head is 2xcmyk roughly half it if light inks used and again if wt mt. you have to have a regular use for the wt mt colours else it will be a profit drain and a load of hassle. i have just...- woolly

- Post #2

- Forum: General Chit-Chat

-

Mutoh Print Head issues...All nozzles Present

that print head is dirty correct to change the wiper -

VersCAMM PNC5000

i had one of those when new and still have a pc60 but as frank says not worth your time really,, as a cutter only its slow by today's standards but adequate for small jobs. the print drivers will only work on a xp system but to drive as a cutter only most cutting program's will have drivers for...- woolly

- Post #3

- Forum: New Member Introductions

-

SP300V Help please

flexi or versaworks rip if vw then on the layout page. show a picture of the miss printing -

SP300V Help please

off set in the rip or move the origin on the printer over. -

Question Ink plotter pens for my D-75 cutter

3d print an adapter for a standard pen -

Help please! Paper stuck to back of wrap, and now not sticking

superglue seen it on youtube so it must be ok..;) sorry could not resist been there done that, have to start printing as said it will only bite you latter...go on kick the trash can and just do it..- woolly

- Post #11

- Forum: Vehicle Wraps

-

SC545EX not printing at all.

all print tests and setups can be done without a pc connected, hope you mean the 3 very small head fusses not just the main ones. too much pressure normally blows the seals out (got the t shirt) after a rebuild still worked. not a lover of just changing parts with out knowing whats wrong with... -

Roland Truevis VG-640 cutting issues

possibly answer the first bit are you leaving extra material after the back crop marks before cutting off it needs a extra 4-6 ins so the rear media eye is covered else it thinks it has run out of media -

Graphtec stock bulging

my guess is the media does not like bending over the bed and will track poorly not unknown for people to create a table in front and behind for the media to slide on so it does not bend stays flat. presuming you are using all the available pinch rollers..- woolly

- Post #2

- Forum: General Signmaking Topics

-

Printing fine print for labels

depends how well the heads are set up and no defections. recently done similar on a vs540. black only head low, half head speed the vinyl 11 hq. if your bi-directional is off a little then use uni-directional just a thought can you just use one of the two heads to remove any alignment issues...- woolly

- Post #3

- Forum: General Signmaking Topics