-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Question New problem cutting thick material force is up

never touched a 8000 series but from my experience of 7000s fc2250 and mx materials. because you have been doing this for a while presume all normal problems dealt with. next to the pen up down actuator is a small encoder strip and eye with care blow clean. this sets the depth after the first... -

-

Need Help Registration marks process (What am I overlooking?)

what are the faint marks by the first reg mark. it looks like you have printed over a calibration print, if so the eye will fail because its not clean vinyl around the mark. as a note don't place the rollers that close to the edge come in half inch more you will loose a single sticker but the...- woolly

- Post #7

- Forum: Newbie Forum

-

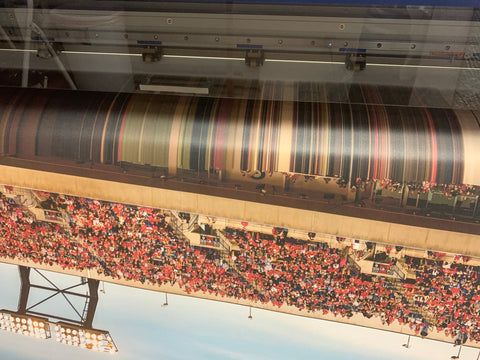

Roland VG540 "streaking" large raster

2in off print is about the printer memory so guess its not allowing the data to flow properly or the computer power management settings may have altered, have a look at the settings and try a nice new shinny cable, i always have spares you never know what happens to them. mine are coiled in to a...- woolly

- Post #8

- Forum: Digital Printing

-

Question what is very clean 540sc needing heads worth?

between the devil and the deep blue sea really, i have had a sc540 pro2 from new and maintained it from warranty end and touch wood works perfectly still used every day, well setup and cared for delivers quality print and cut. dedicated parts are now not to be found but a lot of bits are on your... -

Contour cuts at 40 inches

thanks for the offer see how it goes. keeping the material flat was the big jump forward for us tape a couple of bits of sign board on the machine to test vinyl boxes for legs. then build something better if good., was trying to find pic to show -

Contour cuts at 40 inches

meant to say if you cant get it correct on $2 worth of material dont put in $20 worth -

Contour cuts at 40 inches

ok substance superb material but likes to be kept flat not bending over the bed as you would standard materials, when we used to cut that on a graphtec i built on to it tops (shelf's) so the material stayed flat as it fed in and out, we now use a flat bed for the mx so we can cut then second... -

Contour cuts at 40 inches

other possibility is feed rates set in the printer or vw, in theory the way roland work the cut path after its read the marks should equal it out. -

Contour cuts at 40 inches

with the 540 came new with 5 extra rollers to plug in as required, presumed the 300 would come with 2 extra. i have two 540s and would expect the cut to be no more out than 1 mm at 40 odd ins length. over the years you have probably learnt these but just in case.. slow it down and slow the up... -

Contour cuts at 40 inches

they look fun. what type of material are you using on them. what pressure does it take to cut. do you use extra rollers when cutting, on the vs540 you can get 7 rollers in. as a note if you change the rollers the outer ones are conical and need to be the right way round there is a red dot on... -

Question Feather flag pole pocket - Material

it must be available somewhere but never found it, so when i was making them i used the side off-cut of the flag material, cut a strip any width you want fold and running stich 10 mm in from the open edge, create the pocket and edge to sew the flag to. feed the flag edge in between the flap...- woolly

- Post #2

- Forum: Sublimation Printing

-

Why with these horrible pop ups.

no sorry can't live with that, what was the management thinking.- woolly

- Post #23

- Forum: Site Help and Suggestions

-

Dealer refuses to sell just parts

didiprint do there own make cap top and original one for the vs after about 6 cheaps one had to concede and use a real oem one, just could not get the cheap one to seal properly they were dimensional correct thought the rubber to be to stiff -

Turn off Perff Cut FC8600

perf cut i think is line type and can be turned on and off in any of the conditions, i find the graphtec menus hard work so set a condition that is just normal cut only say condition 2 as con 1 should be pen only set con 3 for perf cutting so you could have two files 1 sent as con 2 to do a... -

Suggestions just replaced print head colors are off SP300V

well done thats a lot better but being really picky could go a whisker more. by degrading i mean look at the definition of the black lines compared to magenta this is age or maintenance related, as you have just done new cap top check its sealing 100%. double check the pump action it may start... -

Suggestions just replaced print head colors are off SP300V

the head is starting to degrade which is not helping looks like a tweak on the Bias Adjustment_mechanical would help. -

Tiny white dots in blue and black parts of the print

you have to think how the colours are made. to print black may have 4 colours on top of one another not just the black ink so to have a random hole all the heads have to told not to print at that spot, comes back to the media rejecting the ink at that random spot only. normally shows as fish... -

Question adhesive paper label stock

i use exhibition mat white vinyl odd sizes got to be quicker that setting up and cutting loads on sra3 sheets- woolly

- Post #2

- Forum: Product and Supplier Referrals

-

Tiny white dots in blue and black parts of the print

interesting, in a lot of the colours that show the white dots are made up of several colours so two or more heads have to have the fault at the same time - place. if interference or loose cables then i would have thought the dots to have one of the make up colours in it. so probably back to... -

Looking for Roland ColorCamm PC-600 Printhead

your long shot may of come good but i need to check where i think it is, but cant do that till fri. where in the world are you AZ Arizona ? i am in the uk. best message from now- woolly

- Post #2

- Forum: Member to Member Classifieds • Wanted To Buy