-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

-

-

How much should I charge for 20 truck trailor lettering/decals for each of them 75 squre ft dealingr

Reminds me of many customer calls I get .... " How much is a sign?"- eahicks

- Post #28

- Forum: Sales, Marketing, Pricing Etc.

-

The perfect hem

Yes, this....and we keep old worn out squeegees on hand and use one to run around the entire banner, as well as a J roller. One more thing....roll the banners IMAGE OUT and the hems will not buckle.- eahicks

- Post #27

- Forum: Newbie Forum

-

Looking for old Mustang font

The actual emblem looks to be Times New Roman Bold, slightly extended width.- eahicks

- Post #2

- Forum: Fonts and Typography

-

-

UV vs Printed Vinyl Pros and Cons

This is the key....less production time, and eliminating the cost of vinyl from the equation. And not having to sub out to a screen printer for large jobs, which we lose control of turnaround time and quality.- eahicks

- Post #22

- Forum: General Signmaking Topics

-

Grimco buys Pioneer!!??!!???

Really? Out of all my vendors, I've had the least issues with them. Get most stuff same day from them if I order before 10 or so.- eahicks

- Post #6

- Forum: General Chit-Chat

-

Grimco buys Pioneer!!??!!???

That would the best thing to ever happen to Fellers.- eahicks

- Post #5

- Forum: General Chit-Chat

-

Printing perfect or good gray colors in Flexi? Saturation color setting?

LOL.... I was not jumping on you.... 30+ years in this business, I know what I'm talking about. I know you can assign spot colors in Photoshop, but once you save that image as TIF or PSD or any other bitmap, that spot color info is out the window and it's all CMYK or RGB, depending on which... -

Printing perfect or good gray colors in Flexi? Saturation color setting?

You would need to make sure your image is a tileable pattern, and set to repeat with .000" margin or space between. Or you'll have to set up your file to be one long image. -

Printing perfect or good gray colors in Flexi? Saturation color setting?

wow ....he said NO spot colors as it is raster. Spot colors do not transfer to CMYK or RGB raster images. -

Mini bus wrap

I've done many of these...here's a time lapse of me working on one years ago....like mentioned, account for the extra depth you will be covering. Log In or Sign Up to View- eahicks

- Post #7

- Forum: Vehicle Wraps

-

Question What causes this? I think I know the answer but....

95% of PDFs we get do this. It's annoying. I just save as .TIF or .JPG depending on the final output and never have lines show up.- eahicks

- Post #2

- Forum: Designs & Layouts

-

Printed/Plotted Vinyl Peeling Away From PVC

Unpainted PVC isn't an issue....we mount to PVC every day. It's the cheap stuff that's more porous than usual that I've had problems with.- eahicks

- Post #9

- Forum: Tips & Tricks

-

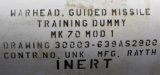

Stencil font on missle

USAAF Stencil could work with some mods.- eahicks

- Post #2

- Forum: Fonts and Typography

-

Printed/Plotted Vinyl Peeling Away From PVC

prepped with 91% or better alcohol first? What brand PVC? I've gotten some cheap stuff before that vinyl did not stick well too...it was the stuff with a clear liner. Never used it again.- eahicks

- Post #6

- Forum: Tips & Tricks

-

UV vs Printed Vinyl Pros and Cons

I don't get this statement.I would think you want to direct print 20 4x8s. I can do 1,000 other things while the printer is running one board, when its done, load another and go do another 1,000 things. Why would anyone be standing there waiting for a board to finish so they can load another? I...- eahicks

- Post #9

- Forum: General Signmaking Topics

-

-

Font Help Please...

Can't find this ugly one....- eahicks

- Thread

- Replies: 1

- Forum: Fonts and Typography

-