-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Mimaki CJV30-130 Mark Detect

The second picture is the one you want to look at. The top lever should be behind the bottom one. Since yours is on top of the bottom one, the rollers probably aren't dropping all the way.- Solventinkjet

- Post #9

- Forum: Mimaki

-

-

Need Help Mutoh 1628x printer

No hard wired fuses that I know of. Most of the newer models have all user replaceable fuses these days.- Solventinkjet

- Post #10

- Forum: General Chit-Chat

-

Need Help Mutoh 1628x printer

It's $198 and I can get it for you but I don't stock them. The only issue is that what is blowing the fuse could just blow the fuse on the new one as well. I would check all the cables and look for any damage/burn marks. Replace them if needed. Feel free to call if you want to order it.- Solventinkjet

- Post #8

- Forum: General Chit-Chat

-

Need Help Mutoh 1628x printer

Check the fuses on the CR board with a voltmeter set to continuity. Most fuses on that model are user replaceable actually so you shouldn't need to solder. I know the fuse for the head circuit on the CR board is a 750mA fuse but this error is specifically referring to the fuse that protects the...- Solventinkjet

- Post #5

- Forum: General Chit-Chat

-

Need Help mimaki cjv150-160 majenta dusting

I have to agree with above. The head surface looks like it has dragged across media a bunch of times, has one fairly large scratch along the whole surface, and it looks like the wiper isn't doing a great job at cleaning the surface.- Solventinkjet

- Post #5

- Forum: Mimaki

-

1324 help

A clogged head will need to be replaced if you aren't able to flush it. We usually recommend it as a last resort. When flushing a head it should feel fairly easy to push through the solution. Feel free to give us a call. We'll be here. Thanks!- Solventinkjet

- Post #6

- Forum: Installation Equipment & Techniques

-

1324 help

Yeah if it sat for about 3 months it's probably pretty clogged which isn't always recoverable. Did solution flow through the head or did it give a lot of resistance? Also, don't pay full price for the head! Ours are OEM for much less!- Solventinkjet

- Post #4

- Forum: Installation Equipment & Techniques

-

1324 help

It means the head circuit is shorting out. Check your head cables to make sure they are installed perfectly, have no damaged or dirty leads, and/or has any other damage along the cable. That's where shorts happen the most. What process did you use to unclog the head and how old is it?- Solventinkjet

- Post #2

- Forum: Installation Equipment & Techniques

-

Mimaki CJV30-130 Mark Detect

Thanks! Take a picture of the area right below the handle on the left of your picture. That's where the mechanism tends to fail.- Solventinkjet

- Post #4

- Forum: Mimaki

-

How to correctly maintain UV printer?

I don't have experience with that head but will tell you that, for example Epson head surfaces are made with Teflon and have fairly sensitive nozzles and they recommend not touching the nozzle surface. A Ricoh head surface is made out of aluminum and they do recommend cleaning the surface but...- Solventinkjet

- Post #4

- Forum: Newbie Forum

-

SP Fuzzy Magenta Edge

The second picture looks like it was from before the bi-directional alignment. The others look like over spray which is usually a sign that the head is failing. You should soak the head to see if that helps with the deflecting nozzle sin your test print. Sometimes that can do the trick quite...- Solventinkjet

- Post #2

- Forum: Roland

-

Any Adobe Scripting Programmer here?

I know this doesn't completely answer the question but if you had each design saved as a separate file, most cutting software will nest it for you. Flexi also has a nesting feature that minimizes waste but you would have to buy that. I know it's not exactly what you're looking for but it's the...- Solventinkjet

- Post #2

- Forum: General Signmaking Topics

-

mimaki 150-75 ink configuration

I always recommend my customers use CMYKx2. I personally do not see a difference when using 6 or 8 colors and I never recommend White or Silver with a solvent machine. CMYKx2 is faster too.- Solventinkjet

- Post #2

- Forum: Mimaki

-

Running ink cartridges dry - how big of a deal?

The machine should stop when the ink cartridge is empty. Sometimes it doesn't especially with 3rd party inks. In that case all that happens is that color will drop out in the print. If you put a new cartridge in, it should be fine. The small amount of air that gets in doesn't cause a huge...- Solventinkjet

- Post #2

- Forum: Roland

-

Discussion What's the most common design mistake you see made in sign design?

At my first job as a GD in a sign shop the bosses wife was in charge of final design decisions. All I heard all day long was, "Fill the space fill the space!" It didn't matter if it was a simple text 10' 'x 2' banner, the text had to be stretched to, "Fill the space". I turned out a lot of bad...- Solventinkjet

- Post #6

- Forum: New Member Introductions

-

mimaki jfx200 help accessing #test and #adjust

Power on the machine while holding the Function and Remote buttons. The menus will be added to the regular menu set.- Solventinkjet

- Post #2

- Forum: Mimaki

-

Identification tags / text labels for Artworks in illustrator

I would put the cut line in one layer and the label in another. Then just turn off the label layer before cutting. Or if your cutting software allows it, just make the labels a different color and then turn that color off in the software before cutting.- Solventinkjet

- Post #3

- Forum: Adobe

-

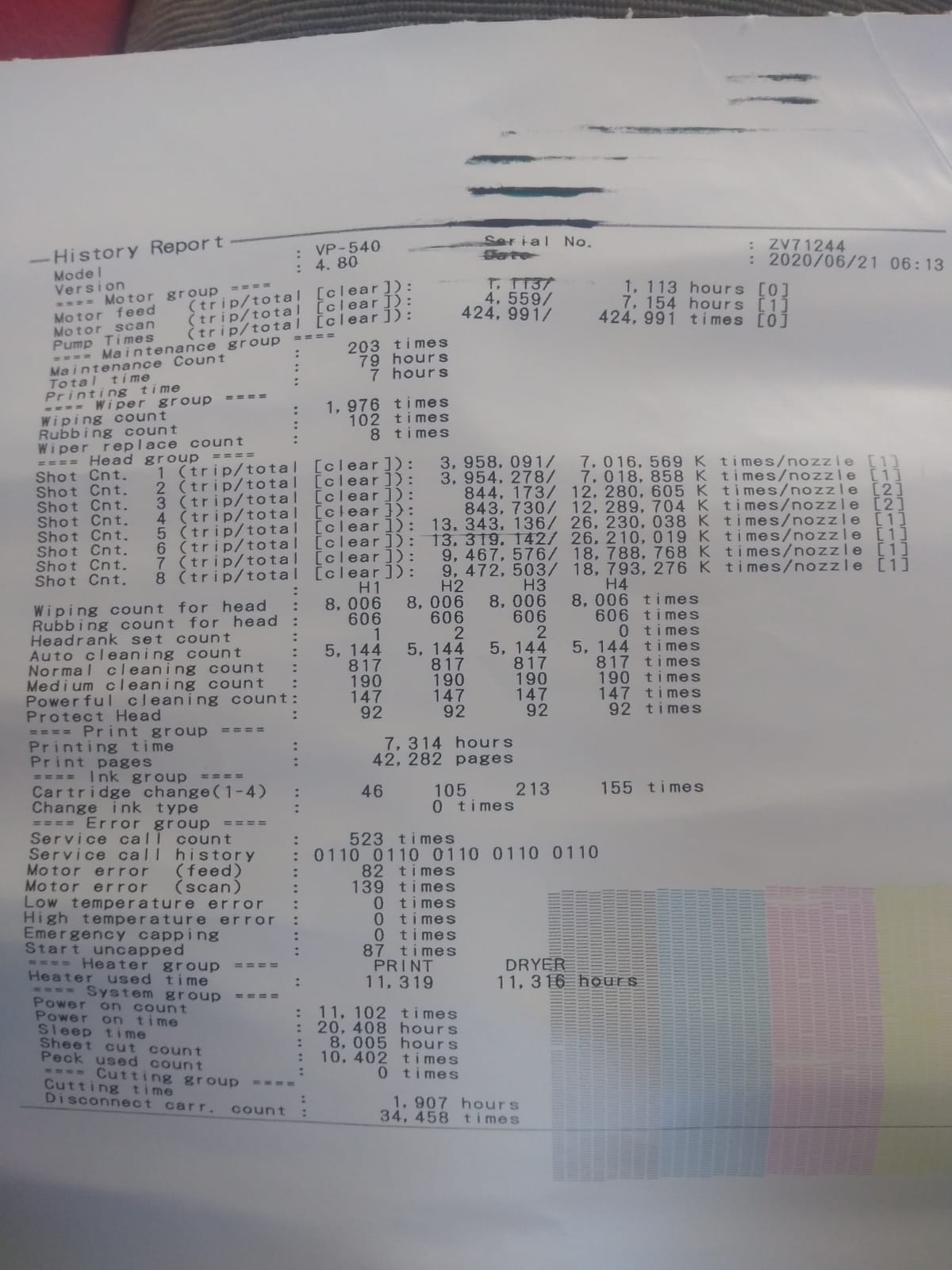

Epson DX4 Deflection

Head 3 has fired more than double the shots it is rated for. head 4 is at about 150% of it's life time. You could try soaking and flushing but at that amount of shots fired, the nozzles are most likely just deformed which causes the deflection.- Solventinkjet

- Post #3

- Forum: Digital Printing

-

Customer Mask Requirements

We require the mask to enter the building. If you don't want to wear one we will bring the order out to your car and give you a mask too!- Solventinkjet

- Post #6

- Forum: General Chit-Chat

-

Mimaki CJV30-130 Mark Detect

Make sure you use the recommended crop mark size when creating the crop marks in FineCut. The longer the print, the bigger the marks need to be. Also, make sure the pinch rollers are down all the way. A lot of the time the tension mechanism in the back fails and that makes it so the rollers...- Solventinkjet

- Post #2

- Forum: Mimaki