-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

How to apply prints?

I would recommend if you're starting out and do not have a 20k budget for a laminating table these suggestions. 5'x10' ( strongly recommended size so you have extra space on the table for trimming 54" rolls of material before mounting.) 3/4" MDF or Plywood top 5'x10' Rhino Cutting Matt 52" Big...- Brandon708

- Post #9

- Forum: Digital Printing

-

-

Need Cob Led Supplier Options

Here is my contact.... Jake Rulander Specialty Lamps jake.rulander@specialty-lamp.com Direct: 814-313-1997 Tell him Brandon from One Up Signs told you to contact him for good pricing.- Brandon708

- Post #4

- Forum: Electric Signs & Channel Letters

-

Best way to deal with seams on multiple face panels across large lighted cabinet?

The larger boxes with hanger retainers are the best way to do that. These boxes are usually 5' or taller and not all of them are properly constructed like that and when they aren't thats where the screw comes in. It was my mistake that I didn't say just a single screw per panel but that was...- Brandon708

- Post #22

- Forum: General Signmaking Topics

-

Best way to deal with seams on multiple face panels across large lighted cabinet?

You dislike my post because I suggest the best wrong way to do this sign. I suggested all the correct ways to make the sign. OP doesn't want to nor does the client have the budget. I suggested the best way for him to do it incorrectly. When I say screw the sign panels in I should of mentioned...- Brandon708

- Post #20

- Forum: General Signmaking Topics

-

Is this a good deal?

You should contact your local Grimco dealer and ask them to get you a quote- Brandon708

- Post #3

- Forum: Digital Printing

-

Damn sun

the best cast laminates are a real pain in the butt to laminate by hand beceause how thin it is. The cheaper laminate crap is easier to apply because its thicker. If your laminating UV prints you are going to run into the issue of the raised ink catching bubbles and enhancing the copy. I would...- Brandon708

- Post #3

- Forum: Newbie Forum

-

Flexi Cloud Update SP5 Build 2898

I have had sp4p2 for a couple months if I can recall without any issues. Should I download the Sp5?- Brandon708

- Post #4

- Forum: Flexi

-

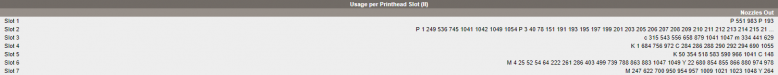

HP Latex + Checking optimizer heads

I was just scanning through the posts again. Did you do a clean all printheads task on the printer yet? Thats the first thing I would of done followed by a color calibration to the media you are using.- Brandon708

- Post #9

- Forum: Hewlett Packard

-

Best way to deal with seams on multiple face panels across large lighted cabinet?

I always try to remember that just because I am doing work for a Non-profit Organization doesn't make my company a Non-Profit Business.- Brandon708

- Post #13

- Forum: General Signmaking Topics

-

Best way to deal with seams on multiple face panels across large lighted cabinet?

If you insist on doing 4 panels then you can cut 2"x48" inch strips of polycarbonate (clear would be best) then bond them together with weld-on in the back of each panel 1" exposed to give you a retainer strip to hold the panels together so they don't bow at the seams. I would also screw the...- Brandon708

- Post #6

- Forum: General Signmaking Topics

-

Best way to deal with seams on multiple face panels across large lighted cabinet?

why not just order a 4'x50' piece of polycarbonate? Although I would suggest looking into a flex face for this light box.- Brandon708

- Post #2

- Forum: General Signmaking Topics

-

Reflective aluminum signs

Im pretty sure HallSigns can do them white. They are not on their website though. You can get away with doing bare aluminum then paneling it with reflective vinyl. They have good prices but they always take very long like a couple weeks to ship. BTW Grimco does have 4x4 .080 blanks in bare aluminum- Brandon708

- Post #13

- Forum: Newbie Forum

-

Reflective aluminum signs

Mark, If you need someone to print it for you I may be able to help. I print on EG Reflective and laminate it. I can send you the vinyl printed and you can apply it to your 4x4 aluminum blank. That would save on shipping costs instead of me shipping 4x4 panels to you. Although I can do it...- Brandon708

- Post #11

- Forum: Newbie Forum

-

HP Latex + Checking optimizer heads

If I where you I would pull all the printheads and inspect them. It may not just be the optimizer print head.- Brandon708

- Post #7

- Forum: Hewlett Packard

-

HP Latex + Checking optimizer heads

Like Dan said the heads do get damaged and the little strips on the sided will hang and cause imperfections in the prints. You will also hear it scraping along the media so you probably should of noticed that initially. If HP sends you a print head they will want you to send them the defective...- Brandon708

- Post #6

- Forum: Hewlett Packard

-

HP Latex + Checking optimizer heads

I don't know of a solution for this other than changing the printhead. If its under warranty call HP and let them know and they will send you a new one. Sometimes I have even gotten them next day.- Brandon708

- Post #2

- Forum: Hewlett Packard

-

Installing All New Light Fixtures In My Shop/studio, Any Advise?

Thank you!- Brandon708

- Post #18

- Forum: Tips & Tricks

-

Rant Some Customers......

We have all realtors pay in full when they order with the exception of a few long time customers that I know are good for it.- Brandon708

- Post #19

- Forum: Entertainment, Humor and Spoofs

-

Installing All New Light Fixtures In My Shop/studio, Any Advise?

What LED color temp is closest to D50?- Brandon708

- Post #14

- Forum: Tips & Tricks

-

Every Installers Nightmare

I saw this on the news this morning. Not only did the "sign" fall it landed on his head first.- Brandon708

- Thread

- Replies: 4

- Forum: Installation Equipment & Techniques