-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Need Help laminating..

Center it up and use a good tape measure to get the rolls straight..the media and the lamination. As long as your laminator feeds straight, you should be fine.- WYLDGFI

- Post #2

- Forum: Tips & Tricks

-

-

First Surface/Second Surface terminology

Yup...we use it internally as well as with clients. Our clients are like yourself of unclebun above and already have the need for 1st or 2nd surface worked out. This way everyone is on the same page. Internally....first surface, isn't used much as its the "standard" of our printing and such...- WYLDGFI

- Post #5

- Forum: General Signmaking Topics

-

First Surface/Second Surface terminology

We do our printing as first and second surface. Second Surface meaning reverse facing out is correct for the terminology. Basically you need to train your clients or give them Your terminology and educate them as you go along if you are able.- WYLDGFI

- Post #2

- Forum: General Signmaking Topics

-

CE6000 - cut fully through material with mat

Do you have your blade holder seated properly? On our 8000 the blade holder deceives us where it seats. We always have to make sure it seats fully in the down position or top of the blade holder.....Not midway. -

Fletcher Substrate Cutter

We have had one of those for a number of years. There are ups and downs....the standard blades seem to create "wavy" cuts if you are not careful!! The ACM cutting adapter is nice.- WYLDGFI

- Post #16

- Forum: Miscellaneous Hardware

-

Need Help UV Ink not adhering to Coroplast signs. (Peeling Ink, Sun Exposure)

Wow...thats a lot fo added labor just to print to coroplast. I would say the Lower ink levels would have worked on the 550. Also changing to CMYK and removing LC & LM if you have those would also help.- WYLDGFI

- Post #19

- Forum: General Signmaking Topics

-

Panaflex/Flex Face

Best bet is to deal with a local vendor if you are not a reseller. I didn't read all the posts here and came in at the end of this posting. My apologies...I didn't realize based on the original post that you were an end user here.- WYLDGFI

- Post #17

- Forum: Product and Supplier Referrals

-

FC8000 Not Cutting Top Inch - Contour Cutting

Maybe your pinch rollers are restricting your width? 1. Scan the media with the pinch rollers WIDER than the media. 2. Open the pinch and bring the pinch rollers in closer or onto the edges of the media. 3. Hit CONTINUE or #4 on your control panel. You now have max width available to... -

White back removable window graphic

That should do the trick for ya. We use that vinyl quite often.- WYLDGFI

- Post #16

- Forum: General Signmaking Topics

-

Super lucky today!

I always joke...Im going to go to AC and put it all on Black!- WYLDGFI

- Post #10

- Forum: General Chit-Chat

-

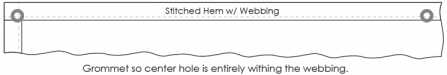

Need Help Grommet placement into reinforced stitching

IF we use webbing for our clients, we put it in the center of the webbing so not to cut through one edge or the other and keep it more intact. If our hems are just welded, the hole goes thru both layers of vinyl with the grommet top just off of center.- WYLDGFI

- Post #3

- Forum: General Signmaking Topics

-

White back removable window graphic

Those are not air egress. The Avery 2921 is. Yea, more expensive...but has air channels.- WYLDGFI

- Post #10

- Forum: General Signmaking Topics

-

Question gemini letters

ASI has the ability to set up a website that's only got retail pricing on it if you are already a member of theirs. We have one as well for our ASI clients and they have their code to look at the pricing there and do a quick calculation and get the wholesale pricing based on that info. If you...- WYLDGFI

- Post #3

- Forum: General Signmaking Topics

-

White back removable window graphic

I know Avery has the 2921 air egress removable vinyl....printable anyway. Not sure how it reacts to your rapid tack...but its air egress so you may not need it unless you are trying to improve adhesion? Its a clear adhesive on that FYI.- WYLDGFI

- Post #7

- Forum: General Signmaking Topics

-

Anyone recognize this type style?

Goudy Handtooled looks Close...but its not as Flat and Straight.- WYLDGFI

- Post #2

- Forum: Fonts and Typography

-

White back removable window graphic

How long do they need to be up there for?- WYLDGFI

- Post #2

- Forum: General Signmaking Topics

-

-

Suggestions Printers.

Look into the 2500i led for a Hybrid. Depending on your rip software, you don't have to change a whole heck of a lot. New profiles of course...but it gives you quite good speed, a Known variable in an agfa machine already...same purchasing for inks...same printheads.,,and white ink. It would...- WYLDGFI

- Post #7

- Forum: General Chit-Chat

-

Suggestions Printers.

Whats wrong with your Agfa? Your 3200i is roll to roll only?- WYLDGFI

- Post #4

- Forum: General Chit-Chat

-

Printer Dilemma

My suggestion is if you really NEED the 2nd printer then get it up and running after a quote. Maybe do it 1st quarter of the year unless you want to take a write off this year for the parts and labor to repair it. IF you have partnered up with a wholesale outfit and trust them to do good by...- WYLDGFI

- Post #3

- Forum: General Chit-Chat