-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Need Help Mimaki JFX200 printing the blues.

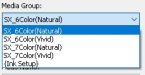

That sounds more like a profile issue to me. Are you 100% no one has been playing with the color settings in Rasterlink? Maybe the default profile was changed?- Solventinkjet

- Post #2

- Forum: Mimaki

-

-

s80600 owners, leave your machine on or off when not using?

The amount of ink spent on cleanings is well worth keeping the head working. If the cost of waste ink is breaking the bank, something is not setup correctly. As a dealer I've had floor models that don't get used very much and only sit there doing cleanings for the most part. In my experience, if...- Solventinkjet

- Post #16

- Forum: Epson

-

Looking for a Rasterlink Instructor

If your dealer tech doesn't offer the service, your best bet is contacting Mimaki directly. They are right there in Georgia so I'm sure one of their techs can help you out. But as mentioned above, watch some YouTube videos and play around with it. That's how a lot of people learn it. Also, PDS...- Solventinkjet

- Post #6

- Forum: Newbie Forum

-

New JV150-130 Owner, Need to Transport

No a cleaning cycle once you get it to the new location. It will get bumped around when moving so there might be some air bubbles that needs to be pulled out but usually it only needs a simple cleaning and you're good to go!- Solventinkjet

- Post #11

- Forum: Mimaki

-

UV T-shirts Possible With Print Media or Need Alternative Ways to Do T-shirts (Latex, DTF). Is allergy to Latex a Possibility?

There is no rubber latex in latex inks so you're good from that perspective. The polymers in the ink are latex like so they call it latex ink which is confusing. Also, certain people are sensitive to UV inks. One guy here on signs101 had a pretty intense reaction to the inks and basically...- Solventinkjet

- Post #2

- Forum: Digital Printing

-

Is this a sign of my printhead(s) dying and needing to be replaced

I'd clean the encoder strip first. It might just be a coincidence that you're only seeing it in the cyan but vertical banding is usually caused by a dirty or damaged encoder. It could be the head but I would change the dampers before changing the head to rule them out.- Solventinkjet

- Post #5

- Forum: Mutoh

-

1641 Page Feed Issue

I'd do the print length compensation in Flexi and see if it works. It can be more of a band aid but if it consistently fixes the issues and doesn't need to be adjusted every time you print, it might be worth trying.- Solventinkjet

- Post #4

- Forum: Mutoh

-

Lines in my print?

Yeah basically anytime you see lines like that it's going to be missing nozzles or a print feed issue.- Solventinkjet

- Post #4

- Forum: Digital Printing

-

Lines in my print?

Looks like you're probably missing nozzles in your nozzle check. Did the person you bought it from train you on the maintenance of the machine at all? There's a few basic things you need to do to prevent the nozzles from clogging. It's possible it needs a new cap top as well.- Solventinkjet

- Post #2

- Forum: Digital Printing

-

1641 Page Feed Issue

You can expect to be +/- about an 1/8th of an inch on prints that long so a whole inch is out of spec. Do you see any sort of distortion in the print? Any banding? If you scroll the material forward using the buttons on the panel, do you hear any thumping noises?- Solventinkjet

- Post #2

- Forum: Mutoh

-

Ink is bleeding?

It's most likely a failing head but you can try changing the head cables out to see if they're causing the issue. What does your nozzle check look like?- Solventinkjet

- Post #2

- Forum: Mutoh

-

Mutoh 1624X MS31 Ink

The newer MS31 inks dry faster so it can dry faster in the maintenance parts as well. They came out with a modification to the waste tubes to prevent the clogging and you can flush cleaning solution through once in a while to prevent it as well. At the end of the day I've had many customers...- Solventinkjet

- Post #2

- Forum: General Signmaking Topics

-

ISSUE WITH LAMINATING UV PRINTED MATERIALS

You will need a laminator with heat assist to allow the laminate to conform with the edge of the ink. I have heard of some people using certain laminates that work better without the heat assist as well so hopefully they will comment.- Solventinkjet

- Post #2

- Forum: Digital Printing

-

Mimaki JV300-160 techs are stumped

You should be able to see ink flowing through those lines during the pump cycle. The fact that you pulled dry ink out of the tubes means they are probably clogged in other places. I would disconnect the tubes from the cap top and try to push cleaning solution through the pump and into the waste...- Solventinkjet

- Post #8

- Forum: Mimaki

-

Anyone know hose schematic for the 3 hoses on capping station?

The pump tubes connect to the two nozzles that are right next to each other and the air release tube connects to the 3rd, offset nozzle.- Solventinkjet

- Post #2

- Forum: Mutoh

-

Need Help onyx12 is there a way to use 4 colors only while ripping ?

On the 2 headed machines you can choose to print with one head but the Super Fine Wave A or B works with a single head. Basically there are 2 channels for each color and choosing A or B chooses which set of channels to print from. So it fires from 4 channels instead of all 8 which does cut the...- Solventinkjet

- Post #8

- Forum: RIP Software & Color Management

-

Need Help onyx12 is there a way to use 4 colors only while ripping ?

If you have a Mutoh ValueJet and are only using 4 colors, there is a mode that allows you to choose to print with only the A or the B channels which can help if you have one channel giving you problems. It's called Super Fine Wave A or B and it of course slows the print down a lot but it does...- Solventinkjet

- Post #5

- Forum: RIP Software & Color Management

-

Employee side business

Haha! Luckily I don't work too much in the field anymore. I'll let my field guy know though!- Solventinkjet

- Post #24

- Forum: Business Management

-

Smallest Desktop Solvent/Latex Vinyl Printer?

That's a good observation because light colors don't add gamut but they do reduce graininess! You need a color like orange or green etc to improve gamut on CMYK printers.- Solventinkjet

- Post #20

- Forum: General Signmaking Topics

-

Smallest Desktop Solvent/Latex Vinyl Printer?

Signs365 prints with Latex machines for their vinyl products and they print at a fairly middle of the road resolution so they can pump stuff out all day. If you want to be able to do fine detailed printing, get anything with an Epson head in it like the Mutoh VJ628, Roland BN20, or Mimaki CJV150...- Solventinkjet

- Post #16

- Forum: General Signmaking Topics