-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

SP300V cutter pressure for laminated?

85 for non laminated it very high which means your blade probably isn't installed properly or is just very worn down. On a brand new blade I usually see 35 grams for non-laminated and anywhere between 85 and 110 on laminated but it completely depends on what material you are using which is why...- Solventinkjet

- Post #4

- Forum: Vehicle Wraps

-

-

-

Need Help sp540v blowing yellow magenta fuse

It's easy to find the transistors once you realize they are the things attached to the large heat sinks on the head board / main board depending on the machine model. They are black and have 3 metal prongs that connect to the board. That being said, transistors are not easy to test like fuses...- Solventinkjet

- Post #4

- Forum: Roland

-

Roland XC540 Air Purge

Yes pull directly from the the part of the damper that normally connects to the head. If the ink has receded far back in the machine, it can take a bunch of pulls. Sometimes it's better to hold it in the pulled position so the ink can flow. Have someone take a look at the lines while you hold...- Solventinkjet

- Post #4

- Forum: General Chit-Chat

-

Roland XC540 Air Purge

If you are using a tapered syringe like I use, sometimes you have to cut the tip off because it is preventing the syringe from making a good seal with the o-ring. Sometimes the o-ring is just too stretched out to seal correctly as well. Make sure neither of those things are happening. After...- Solventinkjet

- Post #2

- Forum: General Chit-Chat

-

Mimaki CJV30-160 Won't cut correct

I have found throughout the years that using FineCut to cut a print that was printed in Rasterlink doesn't always work the best. I have had much more success setting the file up with a CutContour spot color and opening the file directly in Rasterlink. Then print and cut using Rasterlink only and...- Solventinkjet

- Post #2

- Forum: Mimaki

-

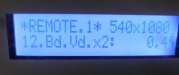

Mimaki J33-130

That is the standard display that shows when you are printing. Remote.1 means you are in remote mode on user type 1 540x1080 is the resolution you are printing 12.Bd.Vd.x2 means you are printing 12 pass, bi-directional, variable dot I'm not sure what the x2 means but I think it might mean...- Solventinkjet

- Post #2

- Forum: Digital Printing

-

Blurry smudged printing roland sp540v

I have seen this pattern on two occasions. 1 was a profile issue where the machine was just laying down too much ink. Make sure your profile isn't double striking or made for translucent vinyl as those tend to lay down a ton of ink. The second one was similar but the heat settings were just too...- Solventinkjet

- Post #3

- Forum: Roland

-

Rant Help Make Our Lives Better: Reform Illustrator's Canvas Size Limit

I'm not sure why you would need unlimited space for vector graphics. If you have to do something large just build it to scale and have the RIP enlarge it. I worked as a graphic designer for a few years before transitioning to the tech side of things and I never needed to make anything nearly as...- Solventinkjet

- Post #4

- Forum: Adobe

-

How Concerned should I be about Gassing Out a print?

I've been in the industry for almost 15 years now and I have never seen laminate fail on a solvent print whether it was laminated right after or 24 hours later.- Solventinkjet

- Post #4

- Forum: General Signmaking Topics

-

Cyan Issue

That usually means the dampers is bad or the o-ring between the ink line and damper is not sealing well. Sometimes the o-ring just falls off and you don't see it. Either way, check if the o-ring is still there and replace it if it is damaged.- Solventinkjet

- Post #10

- Forum: Digital Printing

-

sp 540v Meganta damper has nipple from rubber stuck in it

Never work with the machine plugged in and wait 15 minutes after it's unplugged before you do anything.- Solventinkjet

- Post #7

- Forum: Roland

-

Suggestions VJ 1614 ISSUES....PLEASE HELP

If you have ink in the dampers and the lines above them have no air in them then a simple cleaning cycle should fill the head. Watch the waste tubes as the cleaning cycle runs. Do you see ink flowing through those tubes? If so, then ink is actually flowing through the head and you might have a...- Solventinkjet

- Post #2

- Forum: Mutoh

-

What credit card is good for receiving payment.

So essentially the cost gets passed on to the customer. That could make for some awkward conversations.- Solventinkjet

- Post #33

- Forum: Business Management

-

Help with Cutter Plotte please, Speed, Pess Offset

Speed: On simple shapes and larger jobs you can usually just crank it up to full speed. On more detailed and smaller jobs, you want to slow it down. 30 - 40 cm per second is a speed that should be able to cut most jobs without issues. Pressure: Use the test cut feature and dial it in with trial...- Solventinkjet

- Post #2

- Forum: Mimaki

-

1204a grommet ? turn off

That specific model was designed for printing on pre-grommeted material so that option was added by the firmware and isn't removable as far as I know. You could theoretically put the regular 1204 firmware on that machine and it would get rid of that option but sometimes Mutoh puts blocks on...- Solventinkjet

- Post #2

- Forum: Mutoh

-

Question The Illustrator graphic file is damaged

The best solution is prevention. You should have at least 1 backup of every file on your computer and probably more such as a cloud solution. That way if something gets damaged you can just restore it from your backup.- Solventinkjet

- Post #5

- Forum: Adobe

-

Air bubbles 6 months later...

Recently I had a customer who had a similar issue and it turned out to be the Lexan. It absorbs some of the application fluid and then when it gets hot it expands and creates bubbles according to FDC. You should wait 24 hours after the adhesive remover and then apply dry.- Solventinkjet

- Post #15

- Forum: Vinyl

-

What credit card is good for receiving payment.

This screams scam to me. How exactly do they stay in business if their customers never pay them money and then give their customers free money?! Even Amazon doesn't get a deal like that.- Solventinkjet

- Post #17

- Forum: Business Management

-

Need Help Print length problem

Mimaki doesn't really publish their print length accuracy like they used to but based on older similar models, you can expect to have about a +/- 1/8th inch variance over an 8 foot length. So it sounds like you are actually within spec.- Solventinkjet

- Post #3

- Forum: Mimaki