-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Help with Gerber 1 registration marks

I ran flexi 8 or so on the edge a while back. You have to check two different places for the registration mark color - cant recall where. -

-

Graphtec 7000-130 help please

Sounds like you have it set on sheet mode and it’s teyinf to find the end of sheet? Try setting on roll mode -from the plotter menu -

Need Help Gerber Envision Eye Piece Fix/Cleaning/Replacement

BUY EDGE Registration Eyepiece enVision/Odyssey- Jburns

- Post #6

- Forum: Product and Supplier Referrals

-

Need Help Gerber Envision Eye Piece Fix/Cleaning/Replacement

Of course they sell them - the gerber envision is the machine right? They are like 70 bucks at Hyatt’s- Jburns

- Post #5

- Forum: Product and Supplier Referrals

-

Need Help Gerber Edge FX won't boot up

I believe you hold the F3, and right slew key and wait for it to beep three times.- Jburns

- Post #6

- Forum: Newbie Forum

-

Punching/sprocketing machine for making my own Gerber vinyl?

Durangedesign, Thank you for your information, and you template! Very cool. If I come across one of these original machines I would purchase. -

please help I need to make a decal for the left side an right side of a boat

So it’s a printed graphic?- Jburns

- Post #18

- Forum: Vehicle Graphics

-

Copyright a template ?

Yeah - I agree. Bikes and snowmobiles are around for a few years, then the plastic changes....- Jburns

- Post #4

- Forum: Clipart, Vehicle Templates and Digital Files

-

-

Graphtec CE2000-60 Inaccurate Cutting

that stuff is a little heavy, and slippery on the backing paper. I assume you are unrolling from the roll on the back side of cutter, so the cutter doesnt have to lift it. best case would be to precut the sheet too. -

New Guy Print/cut machine for heavy wraps

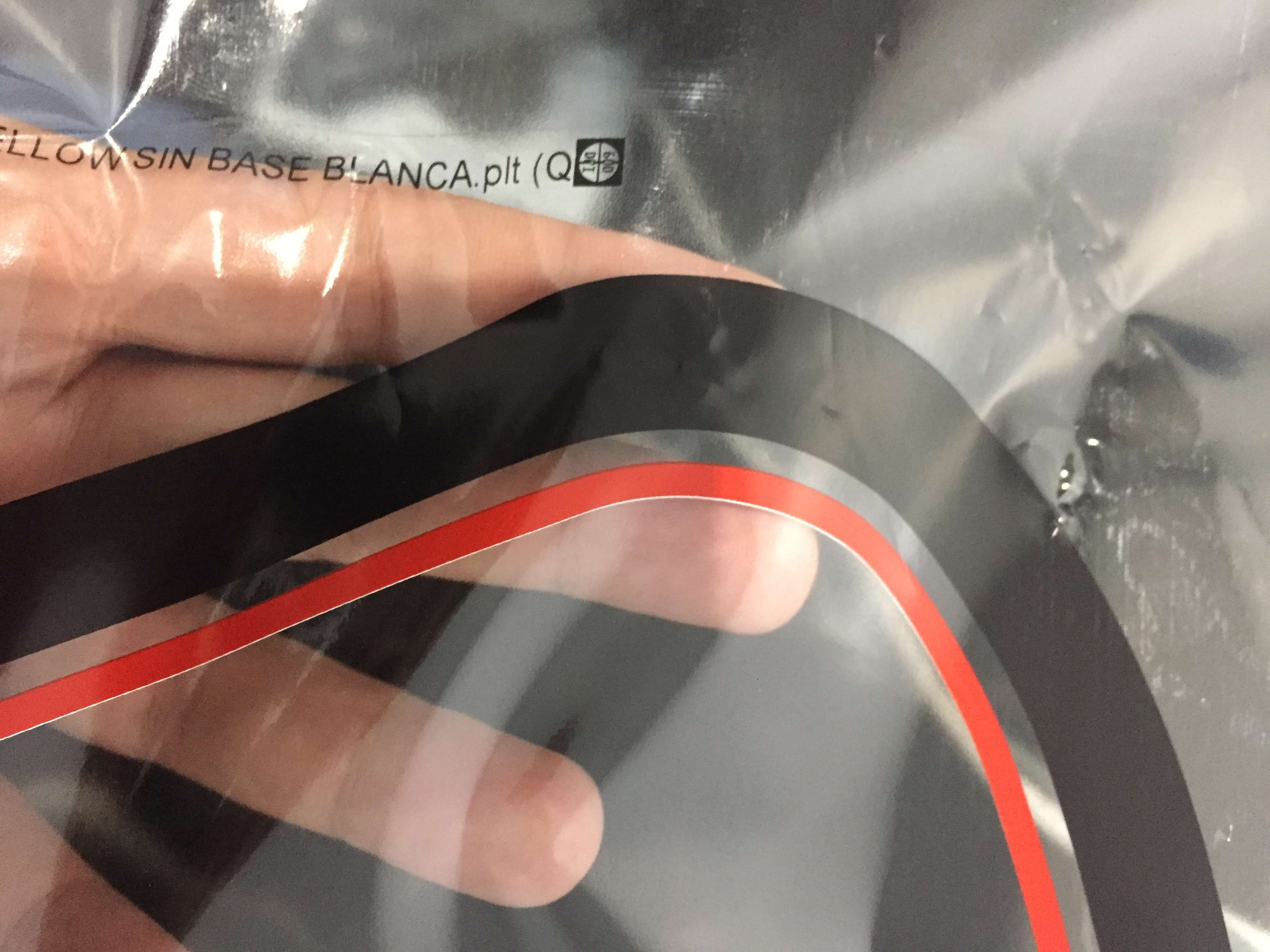

It may be possible to cut on a print and cut machine. Don’t forget the thickness of convex or substance vinyl - they are made for high energy plastics- about 4-6 mil - so you are at 16mil. And at full width this can be heavy after a few panels -for accuracy I would setup a feed table- Jburns

- Post #8

- Forum: Digital Printing

-

New Guy Print/cut machine for heavy wraps

I would use or buy a dedicated Professional cutter for those Thick MX and Snowmobile graphics. i.e. Summa would be my first choice.- Jburns

- Post #5

- Forum: Digital Printing

-

Sign Warehouse Q54 more expensive than 54" Graphtec...... how?

I vote Graphtec on support ALONE! Thats if your final decision is one of these two. -

Need Help accurate cutting

I think it would help the Summa guys and others if you share the type of materials you are cutting - and laminates.- Jburns

- Post #4

- Forum: General Chit-Chat

-

I need a good analogy

Boy, I understand your frustration, especially since they are sign shops. You stated above: They often respond with... "well don't zoom in. Just trace it." Then I would do it. Povide an autotrace in Ai, whatever and - tell them this one is a freebie example of artwork that was submitted.- Jburns

- Post #18

- Forum: General Signmaking Topics

-

Windows 10 and open type fonts

Or can you right click the Flexi icon, run in XP Compatibility mode? -

Anybody had Problems with 75m Gerber Foils??

Yes there is a foil calibration function in the omega software. I have never used it but I imagine it works well. It lays down strips of color and then you make changes in software -

Approximate Thermal Printing Temperature (Fahrenheit)

I want to say 60 degrees C or 140 F. But I will try and verify this weekend- Jburns

- Post #2

- Forum: Digital Printing

-

Question Contour Cutting

My gut tells me the Op didnt leave at least 4 inches of material in front of the front marks, and behind the rear marks. When it tries to find the marks, the media sensors are uncovered. That is my experience with the three graphtecs I have owned.- Jburns

- Post #12

- Forum: Labels and Decals

-

Flexi 10-10.5 Pro Discontinued

I am thinking now. Was it a mistake to sell my dongled version?? No need for internet with that one. I wonder when they will cancel 11 - thats what I have now. At least my gerber software has dongles.- Jburns

- Post #6

- Forum: Digital Printing