-

I want to thank all the members that have upgraded your accounts. I truly appreciate your support of the site monetarily. Supporting the site keeps this site up and running as a lot of work daily goes on behind the scenes. Click to Support Signs101 ...

Search results

-

Just found this on my work table

One evening while sitting around the dinner table my 10 year old son was still bugging me about walking down to the youth center. Seems they were having a special event and I hadn't the funds to give him. I kept telling him no and he started to cry. Next thing you know his little brother had...- myront

- Post #15

- Forum: General Chit-Chat

-

-

Sponsorship Banners

1. brandsoftheworld, wikimedia etc. 2. type in any search engine i.e. "coldwell banker" filetype: pdf (no space before the p) Usually vector logos are used in pdf's 3. email/contact the web designer they usually have a vector or at least understand what that means. 4. recreate if simple...- myront

- Post #28

- Forum: Designs & Layouts

-

-

Question Is my 360 a lemon, and should I buy another HP?

Although we have not had any major issues with our 360, we hate the media loading process and the take-up and....don't get me started. And reds are just impossible. We are looking to add another printer and would definitely lean towards the 560 as the loading process is so much better from the...- myront

- Post #20

- Forum: Hewlett Packard

-

Corel Vector Art

Absolutely beautiful work! Okay, so I'm a car buff too but still... I would add better "starbursts". You can save under the Artistic Media tool as a Sprayer item for quick use at any time.- myront

- Post #24

- Forum: Portfolio Board

-

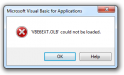

Need Help DRAW X7 Macros stopped working VBA issue?

I did a search for that file on my hard drive. Came up with 2 associated with Microsoft Office. "C:\Program Files\Microsoft Office 15\Data\Delta\root\vfs\programfilescommonx86\microsoft shared\vba\vba6\vbe6ext.olb" (folder) -

Need Help Sign Cut Too Short

So to answer my question. 70" x 70". NOT 70' x 70'- myront

- Post #31

- Forum: Electric Signs & Channel Letters

-

Need Help Sign Cut Too Short

70ft x 70ft? Or 70" x 70"- myront

- Post #24

- Forum: Electric Signs & Channel Letters

-

12'x6' sign without seam?

Have you tried IndyImaging? If you can get the poly/alum in one piece, I'm pretty sure they can print the vinyl that size.- myront

- Post #13

- Forum: General Chit-Chat

-

Suggestions Storefront Window Vinyl - Single Words Layout

Yep, all text the same letter height. Also agree that a condensed font may work best. Inches not points. Point size is meaningless in the sign business.:roflmao:- myront

- Post #13

- Forum: Designs & Layouts

-

Question Onyx Custom Banner Hem

Agree. All bleeds, crop marks,fold line, company logo, and grommet dots are placed within the design. I use my own custom templates and macros to make quick work of it. Send it to a hot folder for the print tech to handle the rest.- myront

- Post #6

- Forum: General Signmaking Topics

-

Template Help

No gettin' around cutting extra. All that should be accounted for in quoting. You charge by the linear foot. Templates are only to be used to give a "rough" proof. More precise measurements before printing are done once the vehicle is on hand. Look for natural breaks and set up print panels... -

How to create table label?

In Corel we made a template to print to heavy card stock. Create a list in Excel. Plug in the names and the cards are filled in for you using Print Merge. Hand cut, score and bend. Made thousands of these over the years.- myront

- Post #6

- Forum: General Signmaking Topics

-

Question Storage for Sheet Materials

We have this same sort of rack in our outdoor garage. We also have this inside climate controlled for foamcore. Rods hang down from the steel roof beams.- myront

- Post #9

- Forum: Product and Supplier Referrals

-

-

Versaworks - Removing all the spacing between copies?

All pfd's sent to us as "print ready" get checked first. How do I check them? Import them into Corel. 9 times out of 10 they aren't the size given by the customer. They either forgot to include a "sign blank" or forgot to include the "artboard" I have no idea. Another annoyance is sending a file...- myront

- Post #21

- Forum: General Software

-

Versaworks - Removing all the spacing between copies?

I see it as the same thing. Either you let the RIP do the "nesting" or multiple copies, or you handle the nesting yourself within the design program. If done within the design program there is no doubt, less margin for error and less time for the Print Tech to set up.- myront

- Post #20

- Forum: General Software

-

Versaworks - Removing all the spacing between copies?

We have found that even after setting to 0 that there is still a gap. Plus we often nest multiple prints together and it's much easier to do by the designer than the Print Tech. If you're left with an odd number of prints you end up with space that cannot be utilized by nesting with flexi...- myront

- Post #15

- Forum: General Software

-

picking up where I left off...

If it were a print and cut and If you know about what has been cut and what has not you could just delete those cut lines and press on. -

Printing Grey with HP Latex 360

You'll end up with a "murky brown" Best result is with R0 G0 B0 or C45 M45 Y45 K100- myront

- Post #12

- Forum: RIP Software & Color Management